Hi! I’m John, and this is my second Cherokee which will be an expedition style build for hunting and camping. I have really enjoyed reading build threads, and I have learned a lot from them, but I don’t have one. Let me start off by introducing my 1998 Jeep Cherokee Sport, McSquizzy. It has the 4.0L I6 that everyone loves, an NP231, and an AX15. I have a D30 up front, and a C8.25 in the rear, with stock 3.07 gears. The previous owner had installed a crummy 200W sub and had an even worse CD player that stopped working when it got hot (I lived in New Mexico). I bought my Cherokee with primer on the header panel and the front drivers fender. It has come a long way from that. The first things I set out to fix were the power door locks (passenger door module), windows that wouldn’t roll down (drivers door module), a slight miss (cap, rotor, plugs and wires), and some paint for the finder and header panel.

The first mod I made to my Jeep was installing my XM radio. I used a piece of 1/2” angle between the visors and ran the power and antenna between the headliner and the windshield. This was great, but I had my windshield replaced a day later, and the guy who did it glued my headliner to the windshield, and encapsulated my wiring in the glue. I did not catch this until later, but when I tired fixing it, I messed up my pristine headliner.

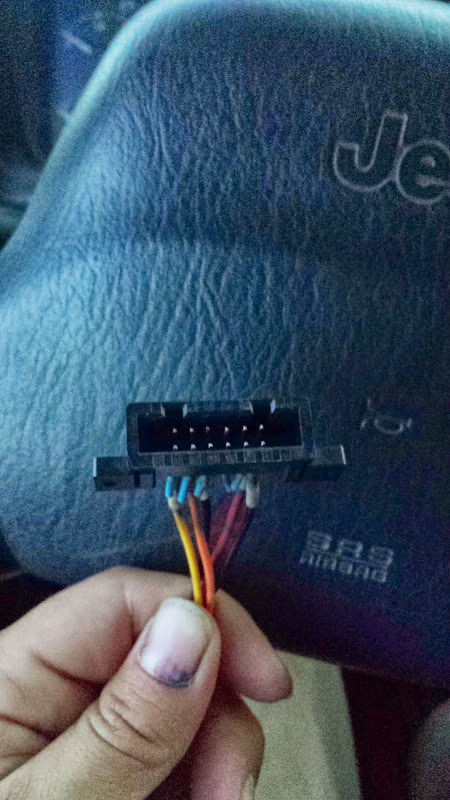

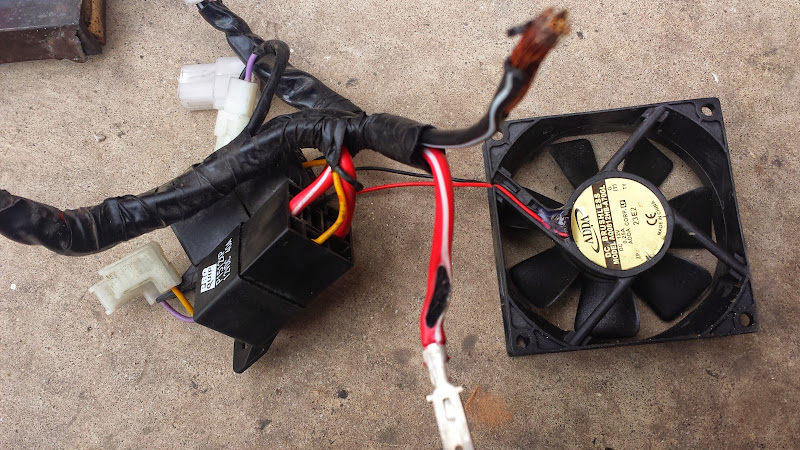

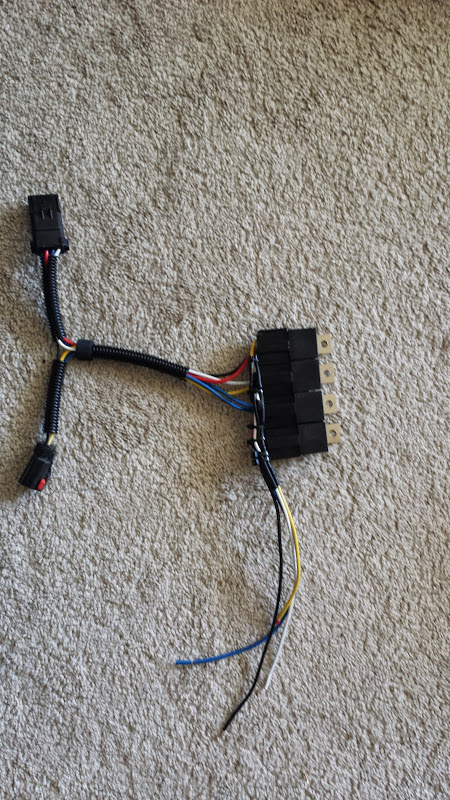

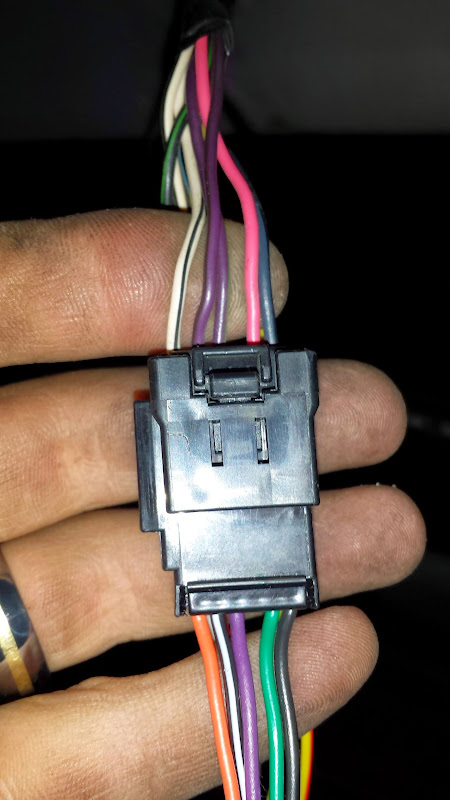

The factory key fob that came with my Cherokee was pathetic, so I decided to upgrade. I installed a Code Alarm CA5150 remote start. I chose it over the normal brands like Clifford that are owned by DEI, because it is manufactured by Audiovox who is the Ford OEM. I had previously had a DEI and was less than impressed, especially with the price, but had always liked the quality of Ford remotes. The previous owner had a Breathalyzer installed at some point, so I had to do some reconstructive wiring. I ended up disabling the remote start due to the fact I could not figure out an effective neutral safety switch. Almost two years later, and I am still impressed with the quality of the Code Alarm unit.

I found a Gentex temperature compass mirror at the junk yard for cheap, and installed it. I reused the temperature sensor and mount from the Suburban I grabbed it from. I brought ACC 12V+ up from the radio.

Temperature sensor mount

Mirror

The first mod I made to my Jeep was installing my XM radio. I used a piece of 1/2” angle between the visors and ran the power and antenna between the headliner and the windshield. This was great, but I had my windshield replaced a day later, and the guy who did it glued my headliner to the windshield, and encapsulated my wiring in the glue. I did not catch this until later, but when I tired fixing it, I messed up my pristine headliner.

The factory key fob that came with my Cherokee was pathetic, so I decided to upgrade. I installed a Code Alarm CA5150 remote start. I chose it over the normal brands like Clifford that are owned by DEI, because it is manufactured by Audiovox who is the Ford OEM. I had previously had a DEI and was less than impressed, especially with the price, but had always liked the quality of Ford remotes. The previous owner had a Breathalyzer installed at some point, so I had to do some reconstructive wiring. I ended up disabling the remote start due to the fact I could not figure out an effective neutral safety switch. Almost two years later, and I am still impressed with the quality of the Code Alarm unit.

I found a Gentex temperature compass mirror at the junk yard for cheap, and installed it. I reused the temperature sensor and mount from the Suburban I grabbed it from. I brought ACC 12V+ up from the radio.

Temperature sensor mount

Mirror