- Location

- Southern Maryland

Hi all,

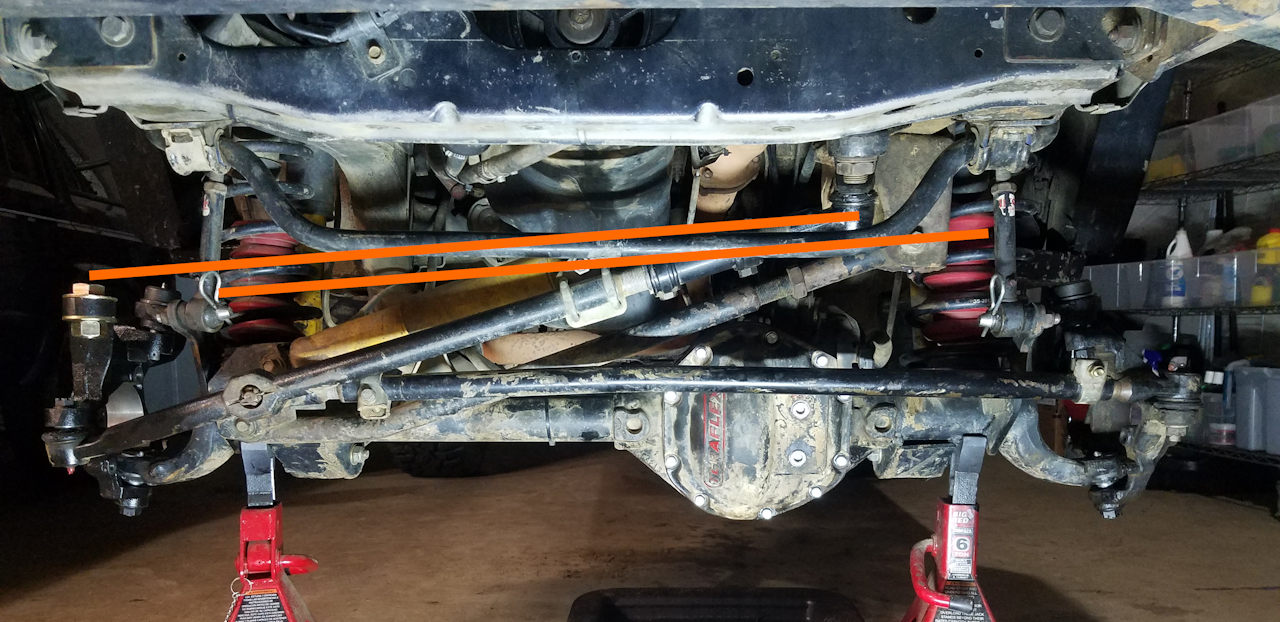

I'm looking for a sanity check on a plan here. The TREs on the Currectlync setup that I've had on my woods beater for the past few years have gotten worked out and there's a ton of slop in my steering anymore. I'm planning to rebuild the front-end to get some additional down-travel and beef things up. I bought a Teraflex high-steer knuckle a while back as a starting point, and this is what I'm looking at:

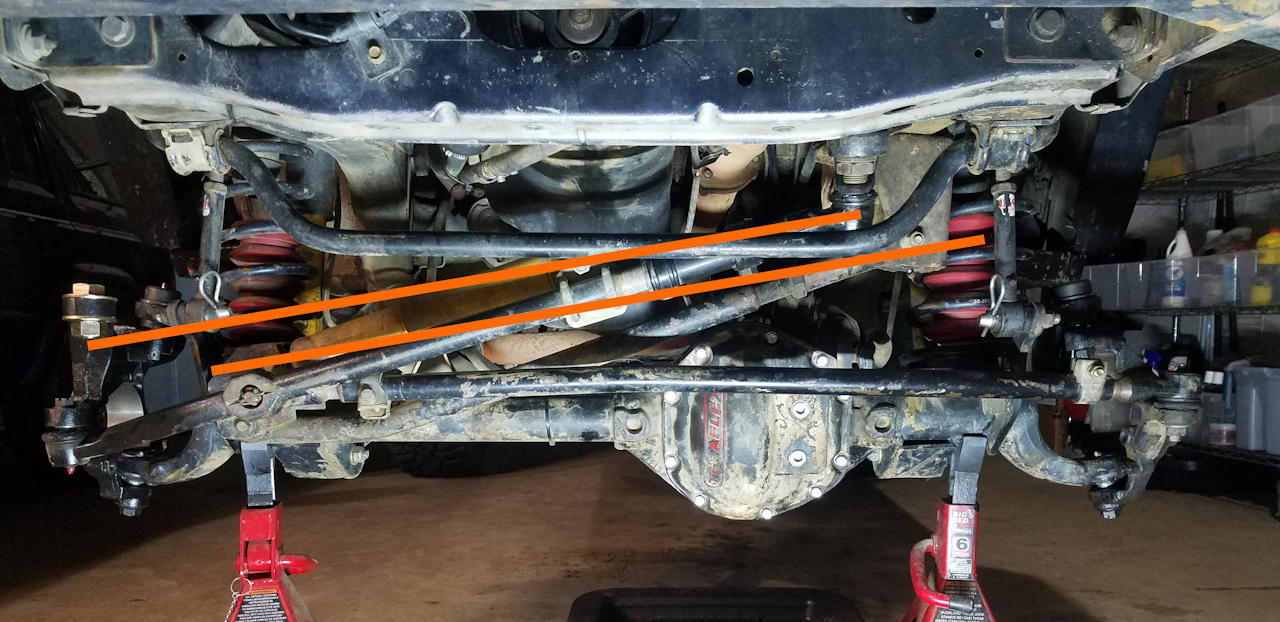

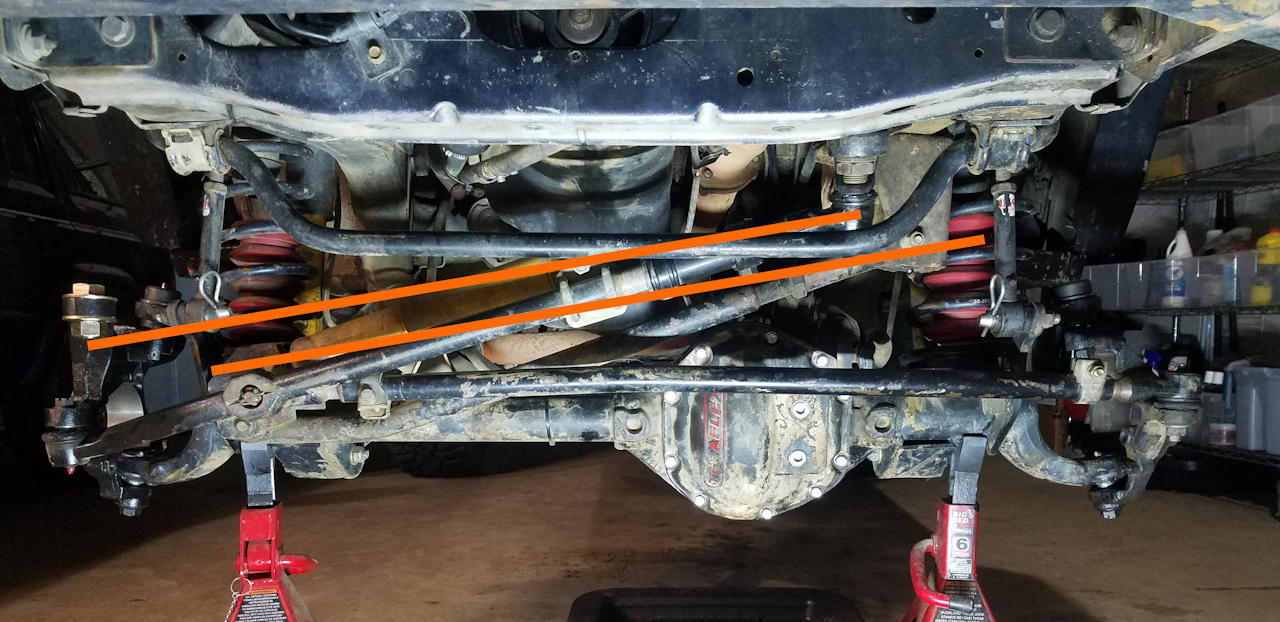

The governing angle is the drag-link to the knuckle. In order to get the trackbar parallel and the same length, I am looking at Stinky Fab adjustable axle-side bracket [1] near the inner C, and an out-boarded body-side bracket such as the Ruff-Stuff outside panhard bracket [2] (or maybe the Alpine Peak bracket [2b]). I may not have enough room to make the links exactly equal. Tie rod will go OTK on both knuckles (assuming the end link will fit below the drag link end, which it should).

Other items on the work list are JCR front stiffeners [3] to beef up the trackbar and steering (using their mids and want to match for fitment), TMR truss that works with this TJ Rubi D44 [4], Undercover Fab UCA passenger weld bracket [5] (had it before), and Artec inner-C gussets.

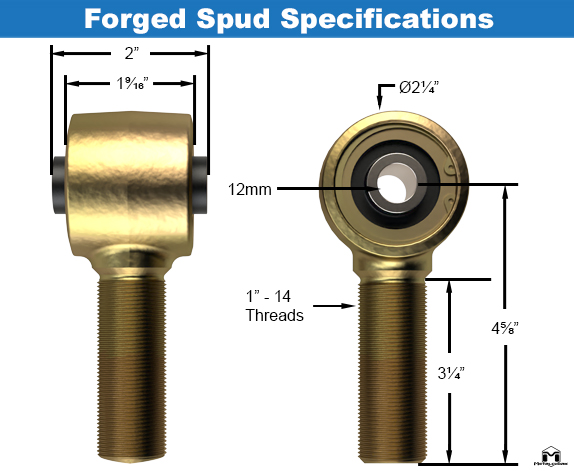

I have not decided on the links or ends yet. I'm favoring Summit Machine ends at the moment. I would probably buy their links too but their order page has gone missing so not sure they are selling those direct anymore. TMR sells some aluminum made-to-order for not too much so might do that. Suggestions appreciated.

Overalll I'm looking for a sanity check, if there will be problems that I'm not seeing.

I'm not interested in doing WJ knuckles or an axle swap, I like the TJ Rubi D44 with RCVs that I have now, and plan to convert/upgrade the outers later.

Thanks guys

[1] https://www.stinkyfab.com/collections/suspension/products/sfr-raised-track-bar-bracket-axle-end

[2] https://www.ruffstuffspecialties.com/R1154.html [2b] https://alpinepeakprecision.com/wp/shop/product/259/

[3] https://www.jcroffroad.com/product/XJUNS-F.html

[4] https://www.tmrcustoms.com/collections/axle-truss-kits/products/jeep-tj-front-dana-44-truss-kit

[5] https://undercoverfab.com/link-susp...pper-control-arm-mount-for-tj-dana-3044-.html

[6] https://artecindustries.com/products/inner-c-gussets

I'm looking for a sanity check on a plan here. The TREs on the Currectlync setup that I've had on my woods beater for the past few years have gotten worked out and there's a ton of slop in my steering anymore. I'm planning to rebuild the front-end to get some additional down-travel and beef things up. I bought a Teraflex high-steer knuckle a while back as a starting point, and this is what I'm looking at:

The governing angle is the drag-link to the knuckle. In order to get the trackbar parallel and the same length, I am looking at Stinky Fab adjustable axle-side bracket [1] near the inner C, and an out-boarded body-side bracket such as the Ruff-Stuff outside panhard bracket [2] (or maybe the Alpine Peak bracket [2b]). I may not have enough room to make the links exactly equal. Tie rod will go OTK on both knuckles (assuming the end link will fit below the drag link end, which it should).

Other items on the work list are JCR front stiffeners [3] to beef up the trackbar and steering (using their mids and want to match for fitment), TMR truss that works with this TJ Rubi D44 [4], Undercover Fab UCA passenger weld bracket [5] (had it before), and Artec inner-C gussets.

I have not decided on the links or ends yet. I'm favoring Summit Machine ends at the moment. I would probably buy their links too but their order page has gone missing so not sure they are selling those direct anymore. TMR sells some aluminum made-to-order for not too much so might do that. Suggestions appreciated.

Overalll I'm looking for a sanity check, if there will be problems that I'm not seeing.

I'm not interested in doing WJ knuckles or an axle swap, I like the TJ Rubi D44 with RCVs that I have now, and plan to convert/upgrade the outers later.

Thanks guys

[1] https://www.stinkyfab.com/collections/suspension/products/sfr-raised-track-bar-bracket-axle-end

[2] https://www.ruffstuffspecialties.com/R1154.html [2b] https://alpinepeakprecision.com/wp/shop/product/259/

[3] https://www.jcroffroad.com/product/XJUNS-F.html

[4] https://www.tmrcustoms.com/collections/axle-truss-kits/products/jeep-tj-front-dana-44-truss-kit

[5] https://undercoverfab.com/link-susp...pper-control-arm-mount-for-tj-dana-3044-.html

[6] https://artecindustries.com/products/inner-c-gussets