Begster

NAXJA Forum User

- Location

- Cape Cod/Boston, Mass

That Jeep must have traveled a long distance and been around the block a few times for it to have a Paragon sticker on it.

That Jeep must have traveled a long distance and been around the block a few times for it to have a Paragon sticker on it.

.hey bud, is that a stock gas tank skid you have?

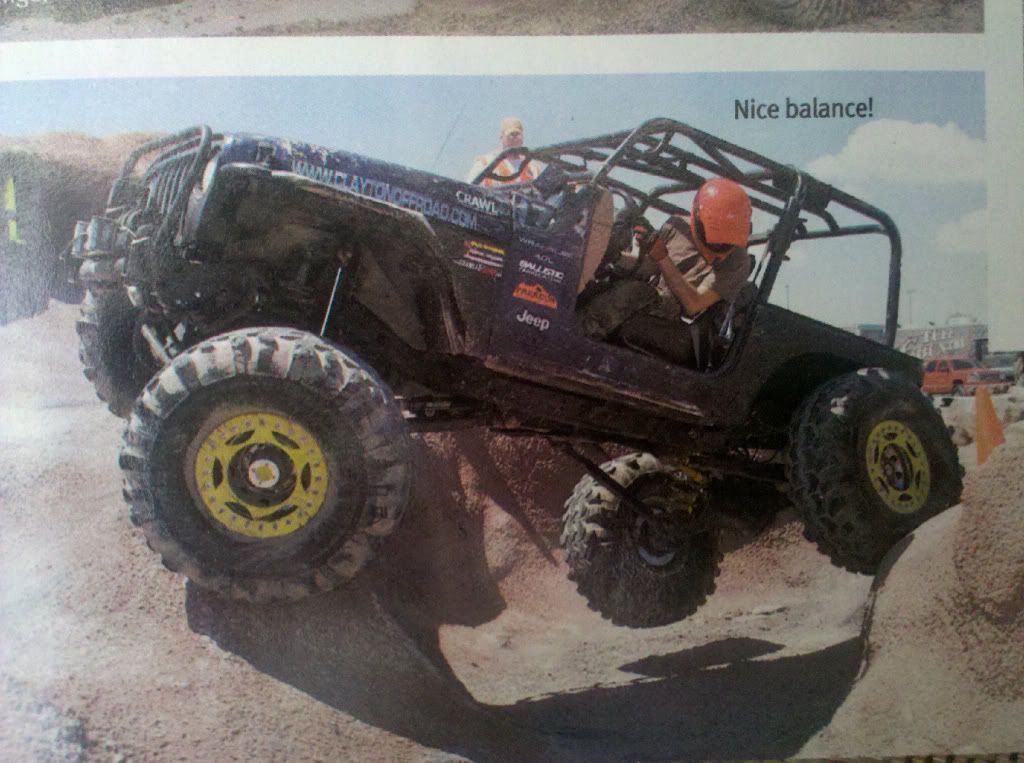

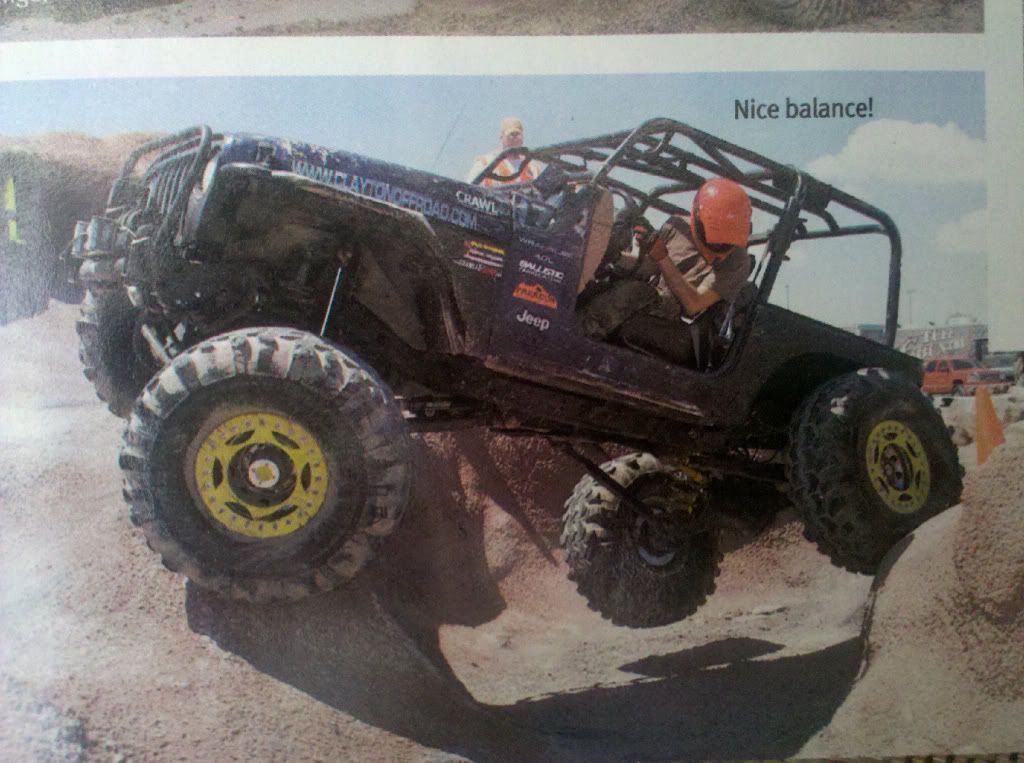

Nice pic dude!I got my pic in Crawl Mag in the new Jeep!

Bumper question: Red xj homemade bumper.

Rear bumper: The main "beam" tubing size... It looks like 2"x6" sq tubing?.....

good job on the flop haha. sick how hight that thing flexed though. why were they towing you through the air?

good job on the flop haha. sick how hight that thing flexed though. why were they towing you through the air?