loki_racer

NAXJA Forum User

- Location

- Pittsburgh, PA

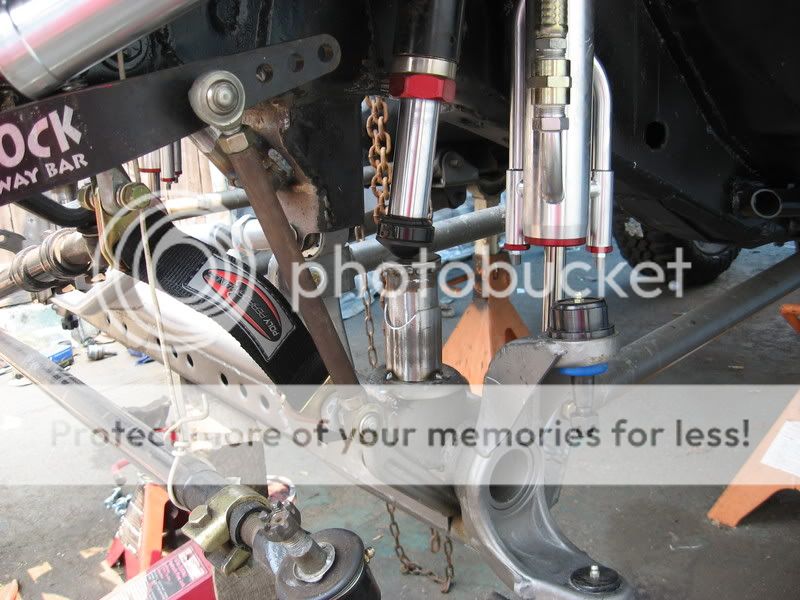

I'm installing the Barnett air bump mount kit tomorrow. Any suggestions about issues I might run in to?

I guess the process is as follows:

When figuring out how high to mount the tube on the plates, should I have the lip of the air bump touching the mount tube?

Or should I leave some space between the mount tube and the lip on the air bump?

I guess the process is as follows:

- Put on stands, disconnect battery, remove tires, remove coils, remove springs, depressurize air bumps.

- Remove reservoir above passenger side coil mount.

- Hack off current bump stop.

- Drill out center hole in the mounted plates.

- Cycle axle up until it's about an inch below full travel.

- With air bump inside the mount kit tube, slide it in to the mount plates.

- Weld plates to frame and tube to the plates.

- Paint

- Reassemble

- Fill bumps with nitrogen.

When figuring out how high to mount the tube on the plates, should I have the lip of the air bump touching the mount tube?

Or should I leave some space between the mount tube and the lip on the air bump?