Begster

NAXJA Forum User

- Location

- Cape Cod/Boston, Mass

Well, I got bored and decided I would make a thread to show what I've been doing to my Jeep for a couple of months now.

I got my Jeep to the point were I liked its looks, and thought it was a pretty good looking Jeep. But I figured something was missing, and it was time to do gears and lockers, and upgrade the axles. Plus, the front steering was getting a little too old, and the holes in the frame side trackbar bracket had opened themselves up some, leaving me with a Jeep that didn't drive straight, and just became a little too unsafe.

I started by picking up a used already built rear D44. It has OX Locker, 4.56 gears, Superior axle shafts which worked out well because they had a 5x5.5 bolt pattern, and RuffStuff truss and raised shock mounts that needed to be welded on.

So, since my garage was a mess, I was once again forced to work outside in my rock driveway. It was a fairly straightforward swap.

I love how rusty everything gets in such a short period of time.

Now for the front axle, I came across Cruisin Illusion's "Custom Width HP44 Build and Tech" thread, and figured that I could handle it. So I picked up a HP44 from a '77 F150. It was dirty, and had a leaky axle seal, but it was in good shape and the guy said the brakes were pretty new.

So I stripped it down.

Cut of all the brackets and Inner C's.

Ordered up the TNT truss, rotated the C's for 5.5* of caster.

It was TIG welded using the Miller welder thats up at my school's machine shop. I did all the welding.

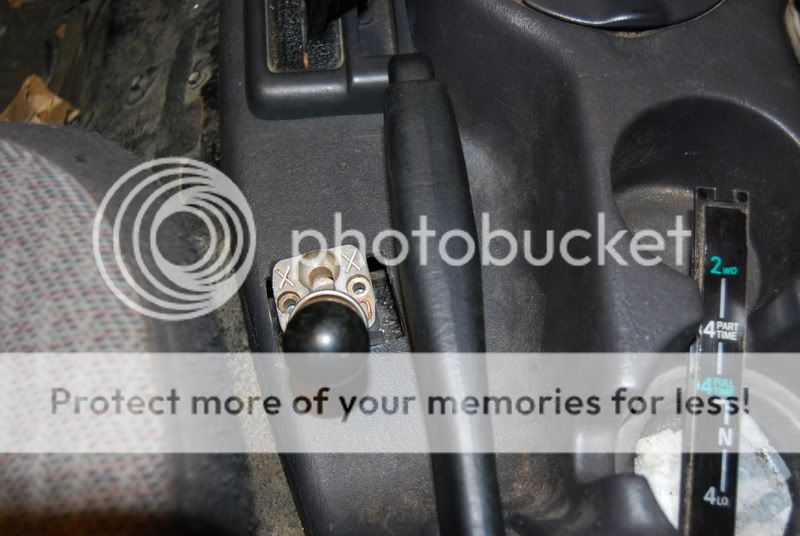

OX and Yukon 4.56 to match the rear. I read a few write ups on installing gears, and figured I would give it a shot. It wasn't too bad after I started to understand what was going on.

Got a coat of POR15.

Got some motivation, cleaned out my garage, and parked my Jeep in there before my dad had a chance to dirty it up again. Stripped the front.

I decided I wanted to do high steer, so I picked up some flattop knuckles, spindles and caliper brackets from a '75 Jeep Wagoneer. I got in touch with John from John Nutter Enterprises, and he was extremely helpful with everything. Great customer service. I highly recommend his services.

Knuckles with Parts Mike high steer arms. The machine work looked excellent, everything fit perfectly.

I purchased Ballistic Fab's inverted T steering kit. Came with Chevy 1 ton TRE's, two pieces of 1.5" OD x .25" wall DOM tubing, and threaded tube inserts so I could make the steering I needed.

Test fitting the axle to measure for the steering. Old coil springs were getting a little tired, and one was bowed pretty good due to driving with poorly repaired CA mounts for a while after they had been bent. So new 7.5 coil springs were used.

I got my Jeep to the point were I liked its looks, and thought it was a pretty good looking Jeep. But I figured something was missing, and it was time to do gears and lockers, and upgrade the axles. Plus, the front steering was getting a little too old, and the holes in the frame side trackbar bracket had opened themselves up some, leaving me with a Jeep that didn't drive straight, and just became a little too unsafe.

I started by picking up a used already built rear D44. It has OX Locker, 4.56 gears, Superior axle shafts which worked out well because they had a 5x5.5 bolt pattern, and RuffStuff truss and raised shock mounts that needed to be welded on.

So, since my garage was a mess, I was once again forced to work outside in my rock driveway. It was a fairly straightforward swap.

I love how rusty everything gets in such a short period of time.

Now for the front axle, I came across Cruisin Illusion's "Custom Width HP44 Build and Tech" thread, and figured that I could handle it. So I picked up a HP44 from a '77 F150. It was dirty, and had a leaky axle seal, but it was in good shape and the guy said the brakes were pretty new.

So I stripped it down.

Cut of all the brackets and Inner C's.

Ordered up the TNT truss, rotated the C's for 5.5* of caster.

It was TIG welded using the Miller welder thats up at my school's machine shop. I did all the welding.

OX and Yukon 4.56 to match the rear. I read a few write ups on installing gears, and figured I would give it a shot. It wasn't too bad after I started to understand what was going on.

Got a coat of POR15.

Got some motivation, cleaned out my garage, and parked my Jeep in there before my dad had a chance to dirty it up again. Stripped the front.

I decided I wanted to do high steer, so I picked up some flattop knuckles, spindles and caliper brackets from a '75 Jeep Wagoneer. I got in touch with John from John Nutter Enterprises, and he was extremely helpful with everything. Great customer service. I highly recommend his services.

Knuckles with Parts Mike high steer arms. The machine work looked excellent, everything fit perfectly.

I purchased Ballistic Fab's inverted T steering kit. Came with Chevy 1 ton TRE's, two pieces of 1.5" OD x .25" wall DOM tubing, and threaded tube inserts so I could make the steering I needed.

Test fitting the axle to measure for the steering. Old coil springs were getting a little tired, and one was bowed pretty good due to driving with poorly repaired CA mounts for a while after they had been bent. So new 7.5 coil springs were used.