- Location

- Cheyenne, WY

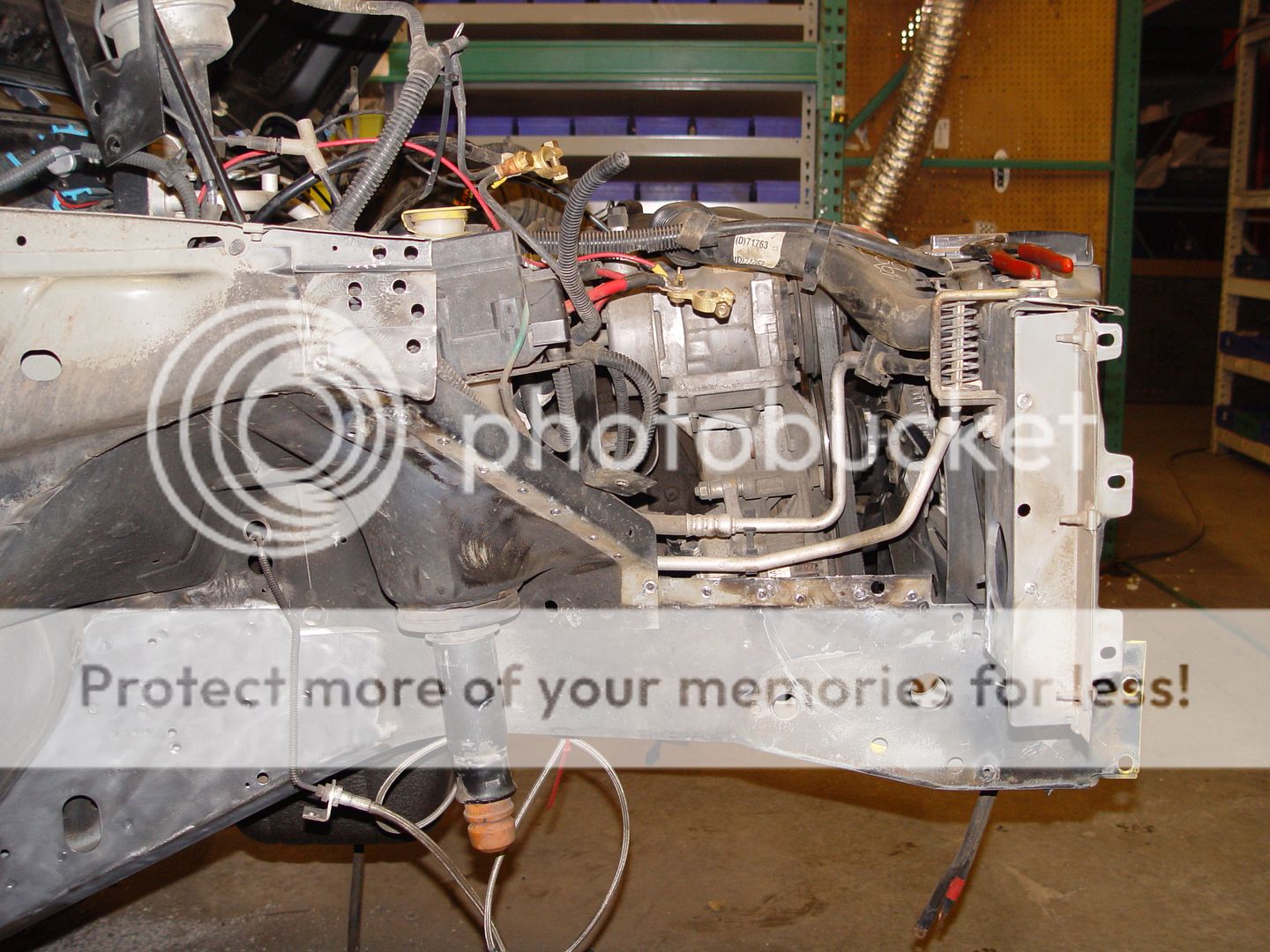

After building TJ's like the HyLine Hemi Jeep and the T&T Lo Rider, it's time to do a LCOG build of a different flavor. After several months of acquiring parts the time has come to bump my XJ up to 37's. Most lift/tire guides say that at least an 8" lift, plus heavy trimming, is required to fit that big a tire on a Cherokee but T&T and crew has once again stepped up to the challenge as we plan to run less than 5.5" with the larger rubber.

My XJ was already equipped with our 5.5" Coil Conversion along with 35" Pro-Comps, Explorer 8.8 rear w/Detroit, trussed HP30 front w/ARB and all our armor.

Before

We'll be swapping a JKD30 w/ARB and 4.88's into the front with our JK truss system. Due to the width of the JK axle we'll be installing a truck 8.8 into the rear along with the previous 8.8's Detroit and a set of Moser shafts drilled to match the JK lug pattern.

My XJ was already equipped with our 5.5" Coil Conversion along with 35" Pro-Comps, Explorer 8.8 rear w/Detroit, trussed HP30 front w/ARB and all our armor.

Before

We'll be swapping a JKD30 w/ARB and 4.88's into the front with our JK truss system. Due to the width of the JK axle we'll be installing a truck 8.8 into the rear along with the previous 8.8's Detroit and a set of Moser shafts drilled to match the JK lug pattern.