Dr. Dyno

NAXJA Forum User

- Location

- Al Ain, UAE

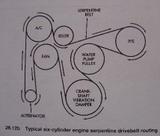

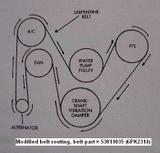

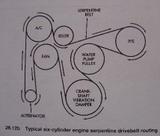

If your idler pulley decides to bite the dust or the mounting bracket bolt hole threads get accidentally stripped when you replace the pulley, there's an easy solution. Get rid of the pulley altogether and reroute the belt. Of course this means you'll need a shorter belt. The stock '92 XJ belt is 2475mm long and the replacement belt needs to be 2315mm long. Lo and behold, the '97-'98 TB belt and the '91-'01 2.5 XJ belt is exactly the right size and carries part no. 53011035, so that's the one that I used when it was time for the idler pulley to RIP. Here are the belt routing diagrams:

It works very well and there are no clearance issues. The resulting modified belt routing is almost identical to that of the '97-'98 4.0 XJ except that the latter has an idler pulley between the PS pump and crank pulley. With the original idler pulley gone, there's one thing less to go wrong. You'd also be able to remove the t'stat housing more easily 'cause the belt will no longer be in the way.

It works very well and there are no clearance issues. The resulting modified belt routing is almost identical to that of the '97-'98 4.0 XJ except that the latter has an idler pulley between the PS pump and crank pulley. With the original idler pulley gone, there's one thing less to go wrong. You'd also be able to remove the t'stat housing more easily 'cause the belt will no longer be in the way.

Last edited by a moderator: