-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Short arms

- Thread starter drkstrurethane

- Start date

denverd1

NAXJA Forum User

- Location

- Dallas, TX

so you're doing a 4 link with raised axle side mounts ? hope you can weld, will be some interesting forces going on every time you press the gas pedal.

I am interested to see this plays out. take some pics.

personally i think you're going to run into issues getting all that packaged in between the axle and oil pan, but will definitely be following along!

I am interested to see this plays out. take some pics.

personally i think you're going to run into issues getting all that packaged in between the axle and oil pan, but will definitely be following along!

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

I have been running a radius arm setup for over 20 years. Everybody said it wouldn't work but a million Ford F-150s and Broncos would argue with you. I even "wristed" the passenger side for easier flex. If you do that, you REALLY need limiting straps.

Ditto and ditto, I'm going on 20yrs with my radius arms and built a lot of "wristed" arms for Ford's! Thought about something "wristed" or just pulling a upper for my XJ but never needed it.

My problem is time. Been running ragged keeping machines going. Also build ing a dump truck in my spare time.

I live to build and burn

Burn baby burn

https://photos.app.goo.gl/sGyTMfJe4G3MBPeP9

I live to build and burn

Burn baby burn

https://photos.app.goo.gl/sGyTMfJe4G3MBPeP9

Black1990jeep

NAXJA Forum User

- Location

- california

I got the Rubicon Express short arms, non adjustable length with the frame drop brackets, 5.5 inch lift, 33x12.5 tires. works fine for me, no problems on freeway or off road. was able to get the caster just right, even with fixed length arms using shims at the drop bracket, although I aboit maxed out the adjustment on the drop brackets. go with adjustable length to be on the safe side I suppose.

Black1990jeep

NAXJA Forum User

- Location

- california

PS get the skid plate on the lower axle side mounts, they will save you damage. Prior owner did not have them, I had to repair them prior to adding the skid plates.

drkstrurethane

NAXJA Forum User

- Location

- arvada, colorado

I got the Rubicon Express short arms, non adjustable length with the frame drop brackets.

Thanks. Are they the super flex?

Black1990jeep

NAXJA Forum User

- Location

- california

Thanks. Are they the super flex?

They are probably 15 years old, Rubicon Express, not adjustable. Uppers have rubber bushes, lower have superflex bushes on axle, rubber bushes on the frame ends. I rebushed the rubber ends when I bought the jeep just over a year ago. The rubber was shot. In hind sight I should have converted them to superflex on all ends. The 15 year old superflex joints showed almost zero wear, the rubber bushes where torn, disintegrated.

Also the uppers should be adjustable, ( adjustable may not have been available back 15 years ago) as I just about maxed out the adjustment on the body mount slots to get the caster right. With wrong caster, the truck drove horrible, now all is nice. but next time, when these rubber bushes fail, I will switch to superflex there, and adjustable uppers.

I installed Rock Hard brand bolt on lower axle mount skid plates, which have saved them more than once from damage. Prior owner did not have these, and I had to fix mount damage do to that.

https://www.rockhard4x4.com/product_p/rh-9030.htm

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

They are probably 15 years old, Rubicon Express, not adjustable. Uppers have rubber bushes, lower have superflex bushes on axle, rubber bushes on the frame ends. I rebushed the rubber ends when I bought the jeep just over a year ago. The rubber was shot. In hind sight I should have converted them to superflex on all ends. The 15 year old superflex joints showed almost zero wear, the rubber bushes where torn, disintegrated.

Also the uppers should be adjustable, ( adjustable may not have been available back 15 years ago) as I just about maxed out the adjustment on the body mount slots to get the caster right. With wrong caster, the truck drove horrible, now all is nice. but next time, when these rubber bushes fail, I will switch to superflex there, and adjustable uppers.

I installed Rock Hard brand bolt on lower axle mount skid plates, which have saved them more than once from damage. Prior owner did not have these, and I had to fix mount damage do to that.

https://www.rockhard4x4.com/product_p/rh-9030.htm

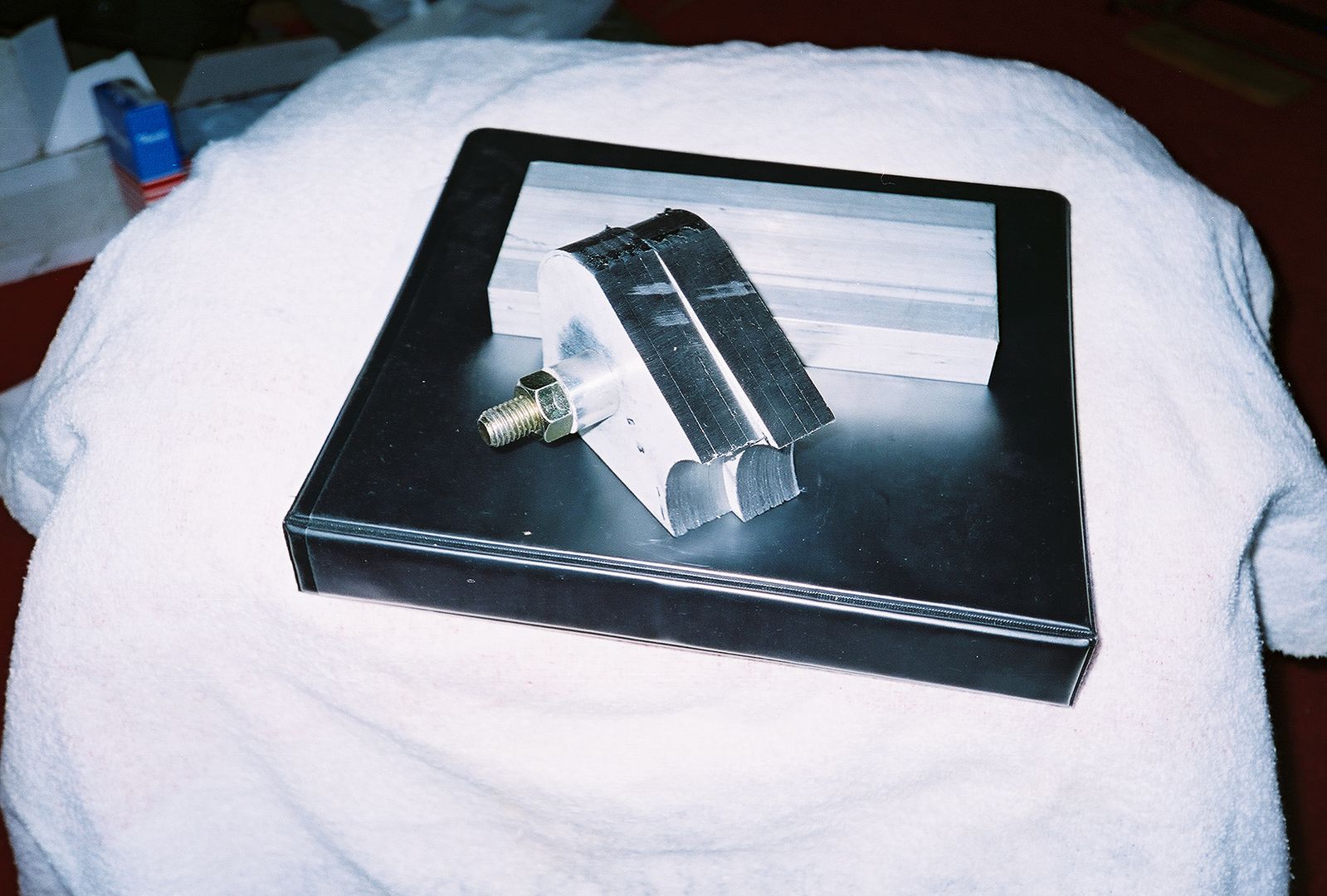

It's obvious you don't weld but those are pretty nasty. Here's a couple sets I made that raises the pivot about a 1/2", as high as I could go with the stock mounting.

Black1990jeep

NAXJA Forum User

- Location

- california

Actually i do weld. But not knowing much about lifted vehicles at all until know, I never considered the need for skid plates on the axle until after I had completely rebuilt the axle, new gears, painted it and assembled it. I being new to jeeping didnt know skid plates existed for these parts, nor much of anything else about how to set up for off road. It has been a steep learning curve.

Had I known I would possibly raised the control arm mounts, but since the axle is now done, installed, and we had a trip coming up, the bolt on plates served well. in hind sight, yes your modification is much better.

I did weld up tears in the existing mounts however. My jeep was modified by prior owner at various shops, some of the work performed was sketchy at best, it is being corrected now. next project is new bumper mounts, the shop had hung a tire carrier bumper off the eight stock sheet metal bumper mounts, it was torn when I bought it! Will be welding frame inserts shortly so my bumper can go back on. heck it was almost ready to fall off! That work was done by a nation chain 4wd parts shop some 15 years ago, lots of horrible work done on this jeep. prior owner paid big bucks (I have the receipts) for labor, and boy was he ripped off by shoddy work. if you want it done right......

Had I known I would possibly raised the control arm mounts, but since the axle is now done, installed, and we had a trip coming up, the bolt on plates served well. in hind sight, yes your modification is much better.

I did weld up tears in the existing mounts however. My jeep was modified by prior owner at various shops, some of the work performed was sketchy at best, it is being corrected now. next project is new bumper mounts, the shop had hung a tire carrier bumper off the eight stock sheet metal bumper mounts, it was torn when I bought it! Will be welding frame inserts shortly so my bumper can go back on. heck it was almost ready to fall off! That work was done by a nation chain 4wd parts shop some 15 years ago, lots of horrible work done on this jeep. prior owner paid big bucks (I have the receipts) for labor, and boy was he ripped off by shoddy work. if you want it done right......

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

In case anyone is interested(it was 14yrs ago) I still have the template in PDF form and one set left in Chromoly.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

That's a baddass template and looks like you have a jig to set it up. Very nice

Do you have any photos of your coil buckets.

Or did you run coil overs or air shocks?

There is only my paper template that I cut out to fit, if you re-read #70 you will see I kept all the other factory mounts just raised the CA bolt.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Oops, forgot those were all hand cut, no jig just all welded together before cutting them out.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

My almost finished axle with my version of BPE's.

Similar threads

- Replies

- 28

- Views

- 994