RossDickman

NAXJA Forum User

- Location

- MI

Instead of looking at all of GL4X4 members rigs I figured I would post up my own build thread for my Jeep Grand Cherokee Laredo ZJ. I'm a 19 year old kid who is going to school to become a Mechanical Engineer and have worked in machine shops and fab shops for a couple years now. I went to tech center the senior year of highschool and learned some pretty cool stuff such as how to run a CNC mill and lathe, manual mill and lathe, surface grinder, etc. Kind of taught myself to weld and do some other metal working things.

I started off by buying a 1998 V8 model ZJ for $1100 that came with some exhaust stuff and two sets of extra tires. Stole the motor, transmission, tcase, doors, axles, steering box, and some other miscellaneous parts. I sold some other things like interior panels, seats, seatbelts etc. A local GL4x4 member came and picked up what was left of the jeep, took what he needed from it, then scrapped it. I ended up a couple hundred bucks in the green from that hole deal after selling tires and such.

That leads to the second jeep I bought off craigslist. A 1998 (same year) Grand Cherokee ZJ V6 model for $400. Craigslist add and the gal I bought it from said that it had a blown head gasket and when I went to go check it out there was two big holes and a couple cracks in the block. I didn't care seeing as I had the drive-line from the other jeep so this deal was perfect. This body / sub-frame was in much better condition and was cheap!

Started the engine swap last winter and finished it in a fairly quick manner. Everything bolted right in besides the passenger side (I believe) motor mount. I had problems getting in running for a week or so and asked many different people and places if they had any ideas and ended up plugging the old V6 computer in. It fired right up but ran like shit so I ordered a new computer and it purred like a kitten for a couple months. I drove it for the rest of the winter, found a good deal on "lift kit" which was arms, coils, and pan-hard bars. Drove the jeep like that for a week or so and realized that just wasn't going to cut it! Which leads the story to where I'm at right now...

Bought a Dana 44 and Ford 9 Inch for $200 and just freshened them up a bit (New balljoints, U-joints, front rotors and calipers, pinion seals, etc.). I built a backbone truss the Ford 9 Inch and did a disk brake conversion on the it with RuffStuff brackets, Rotors are 1978 Ford F150, and calipers, hoses, and pads are 1976 Chevy K5 Blazer. A big thanks to John D for the help with disc brake conversion input!

Seeing as it will be a long travel toy and I've got a place up at Silver Lake, my buddy told me of a sweet deal for some General Grabbers, and I hopped on it. I believe they were $500 for the four 33 X 12.50 X 15's with 200 street miles on them. Bought some steel D-window rims from another member for $60. Plan to beadlock them at some point so I can air down and still whip the back end out and jump in the dunes without rolling a bead in the sand.

Enough background lets get to the pictures:

First ZJ that ended up getting scrapped

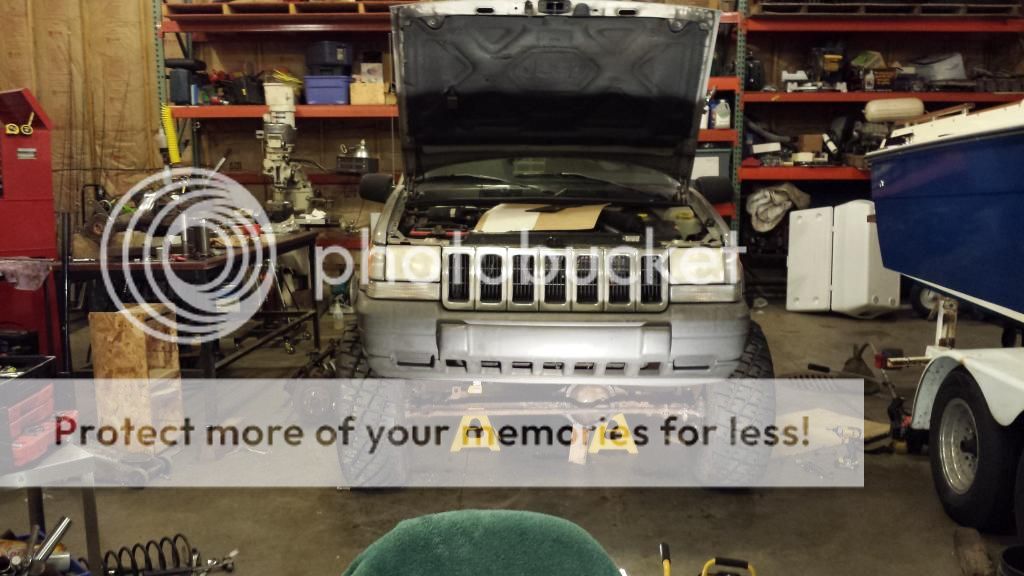

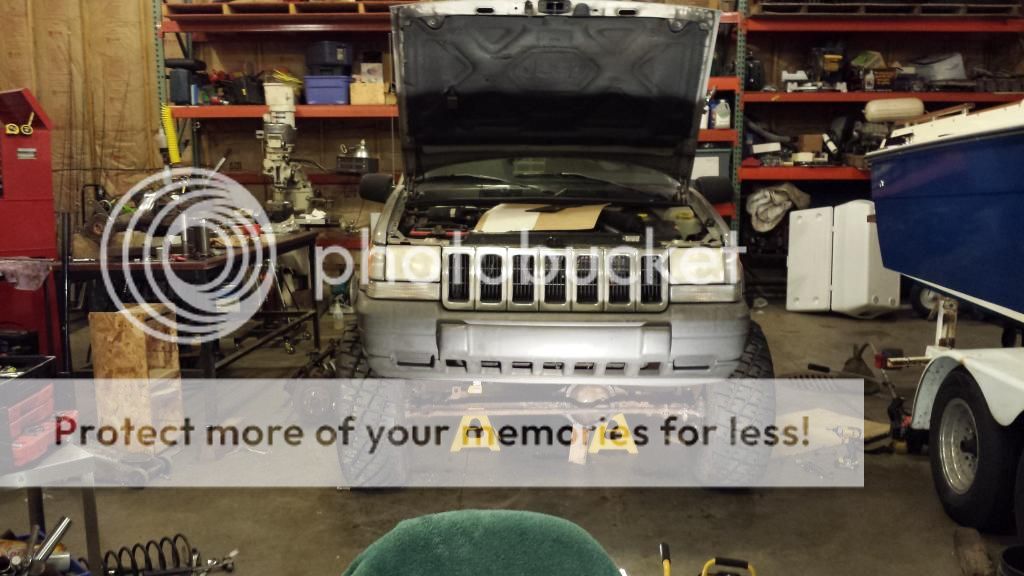

Second ZJ after motor swap and lift

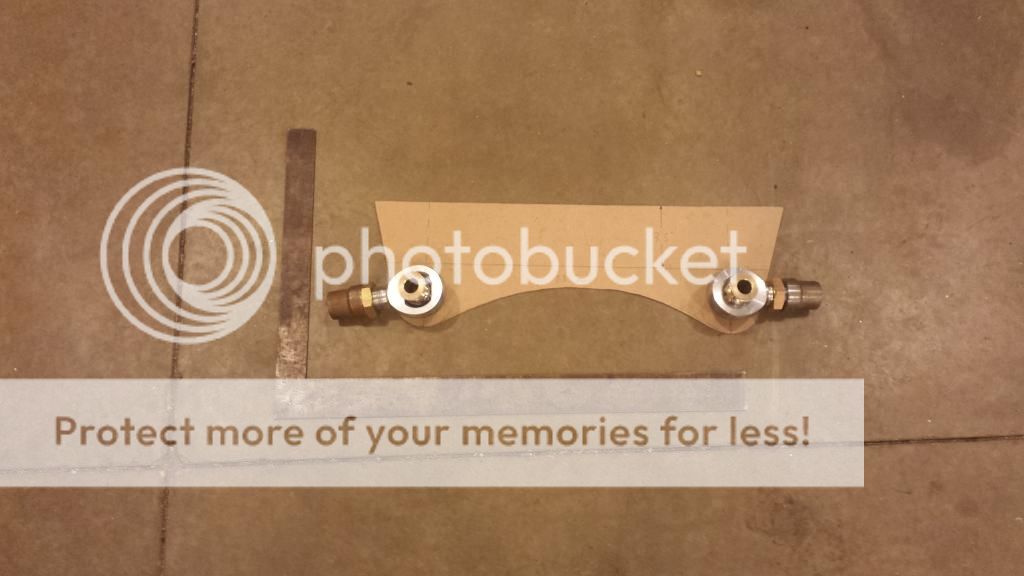

Some of the brake and axle parts

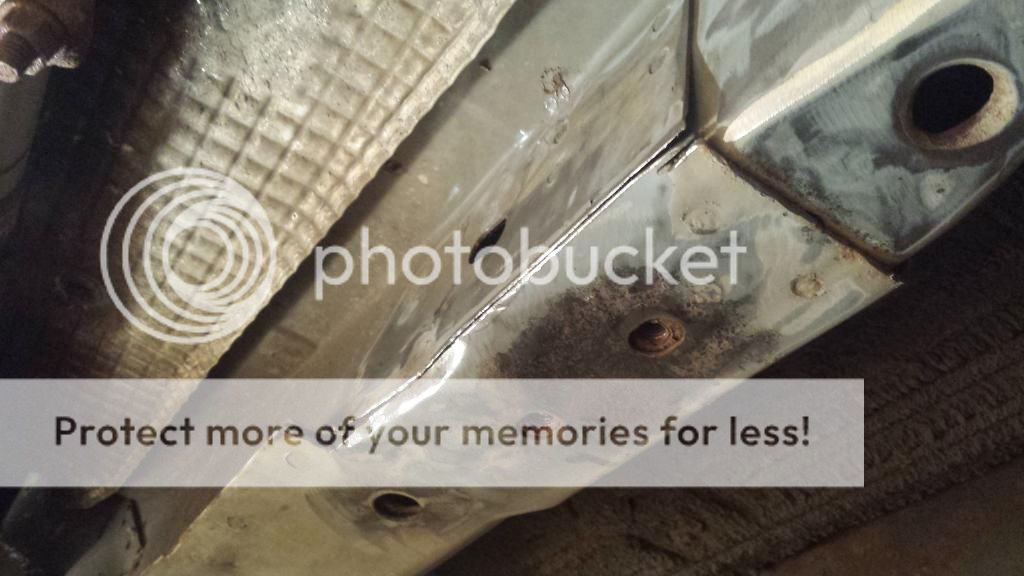

The Ford 9 Inch with the homemade backbone truss (Will also get a truss on the top for the wishbone link mount)

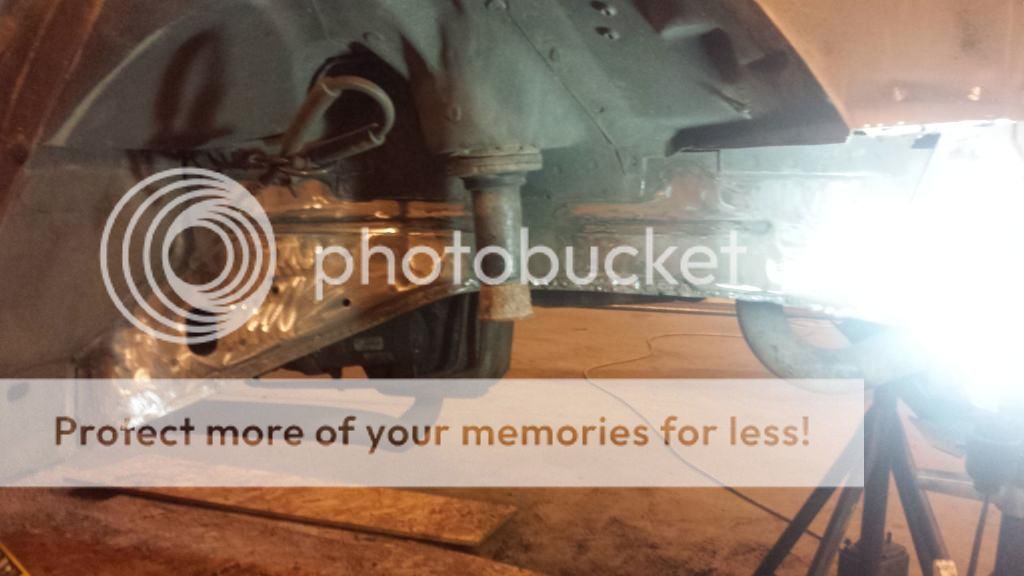

Just the axle and tires setting underneath the jeep to get an idea of width and ride height

Fingered crossed I can get this much bump out of it!

I started off by buying a 1998 V8 model ZJ for $1100 that came with some exhaust stuff and two sets of extra tires. Stole the motor, transmission, tcase, doors, axles, steering box, and some other miscellaneous parts. I sold some other things like interior panels, seats, seatbelts etc. A local GL4x4 member came and picked up what was left of the jeep, took what he needed from it, then scrapped it. I ended up a couple hundred bucks in the green from that hole deal after selling tires and such.

That leads to the second jeep I bought off craigslist. A 1998 (same year) Grand Cherokee ZJ V6 model for $400. Craigslist add and the gal I bought it from said that it had a blown head gasket and when I went to go check it out there was two big holes and a couple cracks in the block. I didn't care seeing as I had the drive-line from the other jeep so this deal was perfect. This body / sub-frame was in much better condition and was cheap!

Started the engine swap last winter and finished it in a fairly quick manner. Everything bolted right in besides the passenger side (I believe) motor mount. I had problems getting in running for a week or so and asked many different people and places if they had any ideas and ended up plugging the old V6 computer in. It fired right up but ran like shit so I ordered a new computer and it purred like a kitten for a couple months. I drove it for the rest of the winter, found a good deal on "lift kit" which was arms, coils, and pan-hard bars. Drove the jeep like that for a week or so and realized that just wasn't going to cut it! Which leads the story to where I'm at right now...

Bought a Dana 44 and Ford 9 Inch for $200 and just freshened them up a bit (New balljoints, U-joints, front rotors and calipers, pinion seals, etc.). I built a backbone truss the Ford 9 Inch and did a disk brake conversion on the it with RuffStuff brackets, Rotors are 1978 Ford F150, and calipers, hoses, and pads are 1976 Chevy K5 Blazer. A big thanks to John D for the help with disc brake conversion input!

Seeing as it will be a long travel toy and I've got a place up at Silver Lake, my buddy told me of a sweet deal for some General Grabbers, and I hopped on it. I believe they were $500 for the four 33 X 12.50 X 15's with 200 street miles on them. Bought some steel D-window rims from another member for $60. Plan to beadlock them at some point so I can air down and still whip the back end out and jump in the dunes without rolling a bead in the sand.

Enough background lets get to the pictures:

First ZJ that ended up getting scrapped

Second ZJ after motor swap and lift

Some of the brake and axle parts

The Ford 9 Inch with the homemade backbone truss (Will also get a truss on the top for the wishbone link mount)

Just the axle and tires setting underneath the jeep to get an idea of width and ride height

Fingered crossed I can get this much bump out of it!