Ok boys and girls, this is it, the first Thread Of The Month for the Jeepspeed section, and I'm going to start with what I think is one of the most important topics you can possibly cover for the XJ... UNIBODY STIFFENING. We all know too well how destroyed our bodies become over time, let's see how you all remedy that!

-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TOTM: Unibody Stiffening

- Thread starter crazyjim

- Start date

ratboy93

NAXJA Forum User

- Location

- alta loma, ca

well i havent had to deal with this plague...YET its only a matter of time before you have to repair the body strengthened or not. i have heard of people laying a plate over a tear in the body but the strength has already been affected. but i do not have any picture proof of plate work to fix tears

xcm

NAXJA Forum User

- Location

- Southern Oregon

heres my front thread, very basic, run of the mill front frame stiffening http://naxja.org/forum/showthread.php?t=1016379

if i was going to do my frame stiffeners again, today. i'd go with ruffstuff again, but i would fab up a way to tie in the stock seat bolts into the frame stiffeners, the outside studs pretty much get in the way, so tieing em in would be allmost effortless.

if i was going to do my frame stiffeners again, today. i'd go with ruffstuff again, but i would fab up a way to tie in the stock seat bolts into the frame stiffeners, the outside studs pretty much get in the way, so tieing em in would be allmost effortless.

xcm

NAXJA Forum User

- Location

- Southern Oregon

=\ thats gonna get messy quick, but ok! i'll pick a couple pics to quote

removed the front axle, loosened brake lines, removed front fender support, cleaned paint,

started on the passenger side, it's easier, there is bending involved, and lets just say im glad i didnt need the upper control arm bolt hole , as it didnt line up.

i started up front, and moved back, bending as i went, as pictured. it came out nicely bent.

on drivers side, had to notch around a tnt trackbar bracket,

in anticipation of new tube bumpers, and a general 'while the welders out' we plated up the front.

had to make up something to replace the steering spacer thingy...

dgrigorenko

NAXJA Forum User

- Location

- Big Rapids MI

here is the centers:

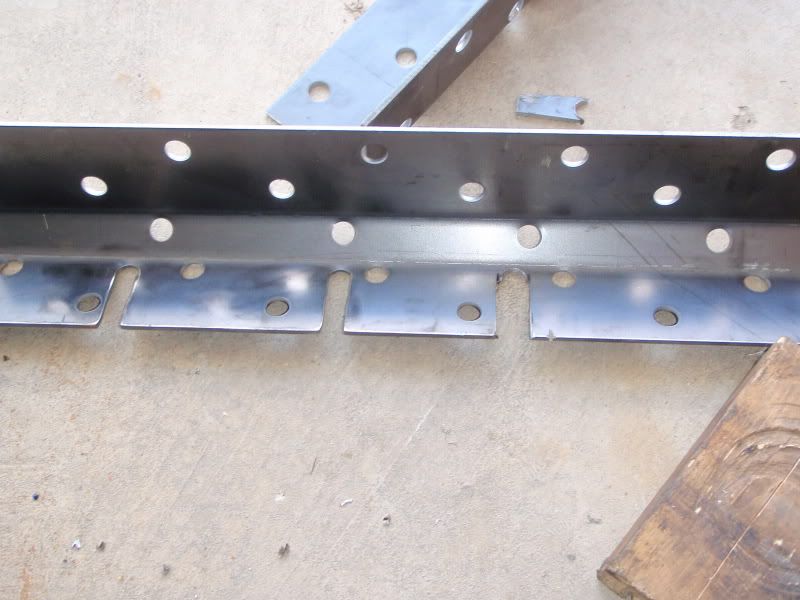

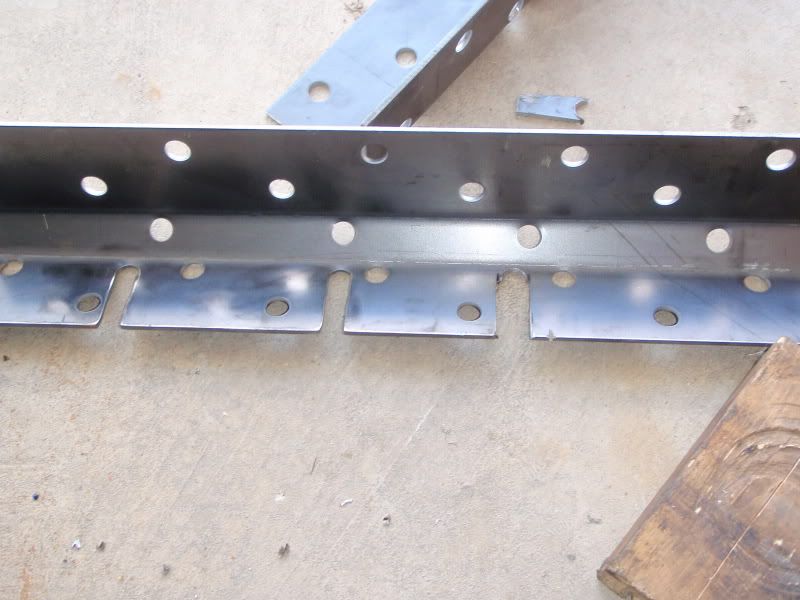

so basically i was getting tired of all the creaking that my jeep was doing even when going around corners, soooooo i went ahead and shelled out the clams (not that many for what you get), and got stiffeners from BRIANHO13 on www.hdoffroadengineering.com. here is what showed up:

at first glance i was pretty happy with what i got, although i was surprised at how light they were, but i suppose that could be because of the bazillion plug weld holes. these are made of 10ga sheet metal, which is slightly thicker than 1/8"(11GA), and slightly thinner than 3/16, which to me was a pretty good compromise of weight and strength.

one of the first things i had to do was modify where they had the crossmember bolt slots due to me having the TNT long arm kit:

next i had to start taking apart some of the crossmember mounting points, and cut off the crush sleeves to fit. i also decided not to completely drop the crossmember, instead i would just lower it enough to slide the stiffeners in

next came the really dirty part: cleaning off the rubber undercoating it went fairly quickly with an angle grinder and wire brush, but what id didnt take off was the paint, which i ended up being happy about. I decided that in order to keep some sort of protection from the elements i would only take off paint where i needed to, and not off the whole rail. i mocked up the stiffeners and with a sharpie i marked where all the plug welds were going to go, and only ground off where i needed to.

I also decided to use some of Krylon's "weld through" primer to prime the backside of my stiffeners. I used this not because i was planning on welding through it, but because it doesnt burn... this way there is still some weather protection, but still no paint where the welding is going to go...

Next came the mounting up... i only had 2 large C-clamps and a hydraulic floor jack, so i started at the front, would clamp and jack, spot weld, and then move back. this method seemed to work pretty well with getting things tight.

then there was the welding.... lots and lots of welding... and moving from side to side and front to back to make sure nothing got too hot.

let me tell you, there are a lot of plug welds on this thing....... IMO its kinda excessive, and something like the ones ruffstuff has is probably more than sufficient.

i then ground things down to smooth them out

Then i used some primer that i have heard good things about, this is the first time i have used it, so i guess i will find out how good it really is. Rustoleum self etching primer... first i cleaned it up with some acetone to make sure everything was squeaky clean, then coated it up. it had great coverage in my opinion so i am happy with it at this point.

I dont have any pics of it with final black paint on it, but i think we get the idea.

Overall thoughts on this install: not that hard, just some good ol grunt work. it took me about 3 evenings to complete, so thats not too bad either. I took it for a test drive and was VERY happy with the results. no more creaking when i drive over a man hole... i even took it up on a rock to flex it, and it barely made noise... this is a vast improvement from what it was. even just the feel on road driving is improved, it just feels much more solid than it was. now a couple of things to consider is that i do have the TNT belly skid tying these together which no doubt helps. I also have a very solid rear bumper, front bumper and the track bar brace, so there are a lot of things tying frame rails to frame rails. i think my next item on the list is plating from the back of these stiffeners to the bumper, and same on the front. i have not decided if i want to get the TMR ones or just make my own...

Final Note: i would like to thank as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

G

so basically i was getting tired of all the creaking that my jeep was doing even when going around corners, soooooo i went ahead and shelled out the clams (not that many for what you get), and got stiffeners from BRIANHO13 on www.hdoffroadengineering.com. here is what showed up:

at first glance i was pretty happy with what i got, although i was surprised at how light they were, but i suppose that could be because of the bazillion plug weld holes. these are made of 10ga sheet metal, which is slightly thicker than 1/8"(11GA), and slightly thinner than 3/16, which to me was a pretty good compromise of weight and strength.

one of the first things i had to do was modify where they had the crossmember bolt slots due to me having the TNT long arm kit:

next i had to start taking apart some of the crossmember mounting points, and cut off the crush sleeves to fit. i also decided not to completely drop the crossmember, instead i would just lower it enough to slide the stiffeners in

next came the really dirty part: cleaning off the rubber undercoating it went fairly quickly with an angle grinder and wire brush, but what id didnt take off was the paint, which i ended up being happy about. I decided that in order to keep some sort of protection from the elements i would only take off paint where i needed to, and not off the whole rail. i mocked up the stiffeners and with a sharpie i marked where all the plug welds were going to go, and only ground off where i needed to.

I also decided to use some of Krylon's "weld through" primer to prime the backside of my stiffeners. I used this not because i was planning on welding through it, but because it doesnt burn... this way there is still some weather protection, but still no paint where the welding is going to go...

Next came the mounting up... i only had 2 large C-clamps and a hydraulic floor jack, so i started at the front, would clamp and jack, spot weld, and then move back. this method seemed to work pretty well with getting things tight.

then there was the welding.... lots and lots of welding... and moving from side to side and front to back to make sure nothing got too hot.

let me tell you, there are a lot of plug welds on this thing....... IMO its kinda excessive, and something like the ones ruffstuff has is probably more than sufficient.

i then ground things down to smooth them out

Then i used some primer that i have heard good things about, this is the first time i have used it, so i guess i will find out how good it really is. Rustoleum self etching primer... first i cleaned it up with some acetone to make sure everything was squeaky clean, then coated it up. it had great coverage in my opinion so i am happy with it at this point.

I dont have any pics of it with final black paint on it, but i think we get the idea.

Overall thoughts on this install: not that hard, just some good ol grunt work. it took me about 3 evenings to complete, so thats not too bad either. I took it for a test drive and was VERY happy with the results. no more creaking when i drive over a man hole... i even took it up on a rock to flex it, and it barely made noise... this is a vast improvement from what it was. even just the feel on road driving is improved, it just feels much more solid than it was. now a couple of things to consider is that i do have the TNT belly skid tying these together which no doubt helps. I also have a very solid rear bumper, front bumper and the track bar brace, so there are a lot of things tying frame rails to frame rails. i think my next item on the list is plating from the back of these stiffeners to the bumper, and same on the front. i have not decided if i want to get the TMR ones or just make my own...

Final Note: i would like to thank

as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back. G

xcm

NAXJA Forum User

- Location

- Southern Oregon

Final Note: i would like to thankas a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

G

x2.

i look forward to larrythedog's contributions here, his front frame/engine bay stiffenening came out AWESOME, and i will be copying him when its time to do the front of mine!

VAhasnoWAVES

NAXJA Forum User

- Location

- Lake City, Mi

well i havent had to deal with this plague...YET its only a matter of time before you have to repair the body strengthened or not. i have heard of people laying a plate over a tear in the body but the strength has already been affected. but i do not have any picture proof of plate work to fix tears

thats not fixing, thats patching.

even with mild wheeling i feel my jeep twisting up when i go out. thats why i plan to add stiffeners BEFORE i even get started up with the go fast stuff. my unibody is strait and id like to keep it that way. i think as far as structural integrity goes, stiffeners are a essential for going fast... i say good first thread jim. ill be keeping up with this one to see if i can get any good idea.

I did my stiffening in 3 stages;

1. TNT / Treks 3/16" plate stiffeners

2. TMR 1/8" front frame plates

3. T&J / Currie Tubular frame stiffeners

I think the combination of the 3 is what made such a difference. I noticed a different right away when I did the TNT stiffeners, my dash wouldn't crack anymore going over bumps, or through driveways. But about a week later the creeks and cracks came back, this is when I decided to go all the way.

1. TNT / Treks 3/16" plate stiffeners

2. TMR 1/8" front frame plates

3. T&J / Currie Tubular frame stiffeners

I think the combination of the 3 is what made such a difference. I noticed a different right away when I did the TNT stiffeners, my dash wouldn't crack anymore going over bumps, or through driveways. But about a week later the creeks and cracks came back, this is when I decided to go all the way.

xcm

NAXJA Forum User

- Location

- Southern Oregon

finnally pics of jim working! is that your shop jim?

and, is that a glasspack?

and, is that a glasspack?

Haha those are old, and no that's my buddies shop where the Jeep lives until she's done.finnally pics of jim working! is that your shop jim?

and, is that a glasspack?

grandrunner

NAXJA Forum User

- Location

- La Quinta, SoCal

heres some of my zj. these are the tnt frame stiffeners. i drilled the holes in.

and undercoated them

and still need to do front and rear plating.

and undercoated them

and still need to do front and rear plating.

Last edited:

Ryan93

NAXJA Forum User

- Location

- San Clemente

I really like how the T&Js "tie" the front and rear suspension together

ratboy93

NAXJA Forum User

- Location

- alta loma, ca

XCM!!!

dude i totally met you one morning in your driveway when i was working across the street from your house.. ill pm you

dude i totally met you one morning in your driveway when i was working across the street from your house.. ill pm you

Some from our racer -

Note that this isn't all that we did. We plated the frame for basically the entire length of the car. The tube stiffener ties the front and rear suspension points together AND also ties bottom of all the cage hoops.

From there, we have a lot of sections in the car where we tied the cage into the body. You can see them along the front fender and along the a-pillar. We have plates like that all over the car.

Note that this isn't all that we did. We plated the frame for basically the entire length of the car. The tube stiffener ties the front and rear suspension points together AND also ties bottom of all the cage hoops.

From there, we have a lot of sections in the car where we tied the cage into the body. You can see them along the front fender and along the a-pillar. We have plates like that all over the car.

tcm glx

NAXJA Member #1033

- Location

- Riverside California

1. TNT / Treks 3/16" plate stiffeners

2. TMR 1/8" front frame plates

3. T&J / Currie Tubular frame stiffeners

I will tell you guys right now... Jim is absolutely right on this subject, and this is the way to go!! Makes a huge difference in performance.

I will also tell you, I have seen many people say " i do not need them yet "..... I would HIGHLY HIGHLY suggest you do this to your XJs as early in the build as you can, it will save you later from having to repair, and replace things.....

Do it first, and save the headaches later!

Larrythedog

NAXJA Forum User

- Location

- Covina CA

Note that this isn't all that we did. We plated the frame for basically the entire length of the car. The tube stiffener ties the front and rear suspension points together AND also ties bottom of all the cage hoops.

From there, we have a lot of sections in the car where we tied the cage into the body. You can see them along the front fender and along the a-pillar. We have plates like that all over the car.

I think this is probably the most important thing you could can do. While the frame plating in key points is critcal, i feel tying the cage to the body everywhere you can will give you the most rigidity possible.

Jaynen

NAXJA Forum User

- Location

- Oceanside, CA

So to what extent can you do those three things without them being tied to a cage? Do they interfere with any other parts you might be putting on so you need to plan for that?

I think this is probably the most important thing you could can do. While the frame plating in key points is critcal, i feel tying the cage to the body everywhere you can will give you the most rigidity possible.

I completely agree here. I'll have plenty of plating once my cage gets finished as well.

So to what extent can you do those three things without them being tied to a cage? Do they interfere with any other parts you might be putting on so you need to plan for that?

If you're talking about mine, it's hindered me a bit but nothing that can't be overcome. It prevents most crossmember's from most long arm kits from just being "bolt on". Bit honestly I'm past the point of bolt on items, and will be building my own arm mounts. Also, I'm still fighting with ideas on where to tie in my cage, there's a good chance my T&J stiffeners will be coming off temporarily.

FiveNdime

NAXJA Forum User

- Location

- Washington

I found this thread because today it was evident that I need to really do something about the twisting. I bet we have all been on the trail and had to open the back hatch and were unable to get it latched again till we got to flatter ground, or just smashed it closed. Today I parked one tire up on a curb stop at the store and when I went to shut the groceries in the back the hatch hit my rear bumper (aftermarket bumper). I really thought to myself that NO, this has to be taken care of NOW, especially since I wheel it quite often. I will be searching and posting up what I will do in the future for my strengthening strategy. This thread has been very helpful thus far.

Similar threads

- Replies

- 28

- Views

- 4K

- Replies

- 0

- Views

- 740

- Replies

- 7

- Views

- 1K

- Replies

- 4

- Views

- 3K