Well I just got a PM request to start a build thread here on  ... so I'll copy what I had started on another forum.

... so I'll copy what I had started on another forum.

You 56k people might want to go and grab a 4 course meal and then come back...

FROM 05-19-2008:

Well I guess its finally time for me to start my build thread. I’ve held off for awhile as it wouldn’t have been much to show other than the come and go of the delivery guys. The “Project Downward Spiral” for the sole reason that as soon as I start something, I end up going all out on it and not really gaining much… yet.

Warning: This build will be slow as I’m on a very limited budget, but I’m trying not to cut corners and do it right the first time. Any suggestions, comments, thoughts are welcomed!

The plan as of today (5/19/08):

- Full width D60s, 5.38s Spooled rear, lockright front, alloyed 35-spline everything, flanges.

- H1s with a 38-39.5” tire

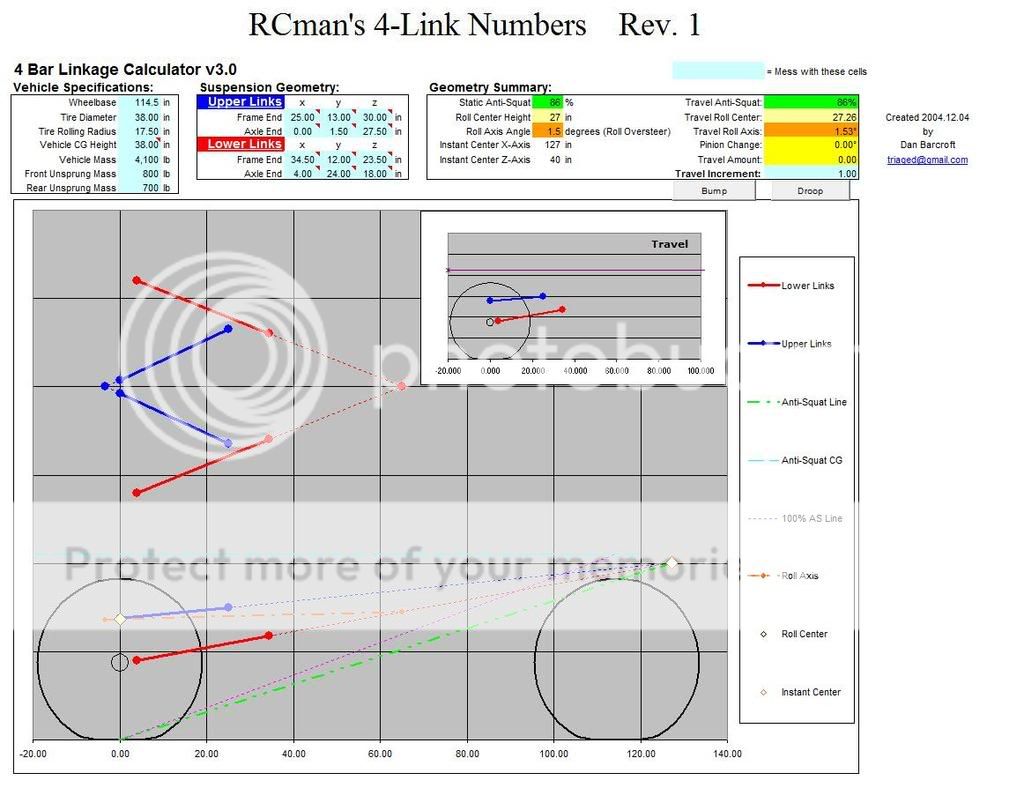

- 4-link rear with coilovers

- Drop brackets/short arms up front, RE springs, ACOS, Fox Shocks ( I know the DBs aren’t the best, but I do have them now so they aren’t costing my anything more)

- Chop the top and more the hatch forward

- Cage, suspension seats, Crow 5-points.

- Other stuff I’m forgetting

I’ll start it off with some history for those that don’t know.

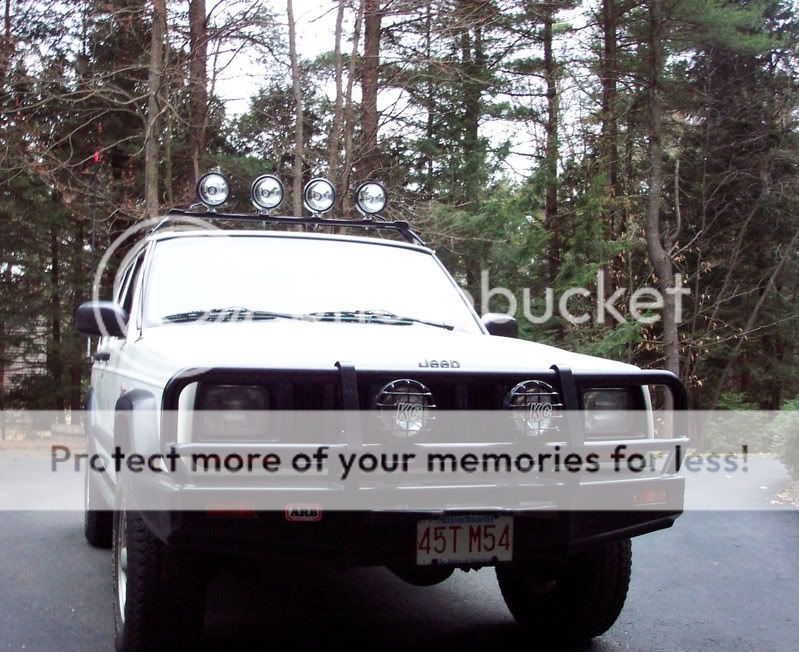

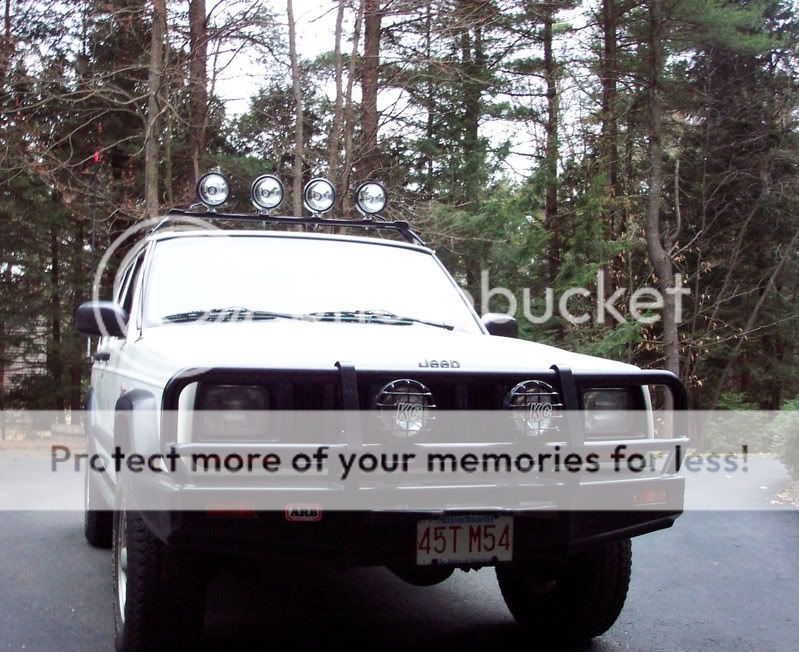

Wheeled it for awhile stock, had some fun, and threw on just over 2” lift with ACOS and new HD leafs. Its now December of 2005 and I’ve got an ARB and C4x4 rails. One trip out I had to much fun in and ended up hydro-locking the engine crossing what was thought to be a small brook. Got it running after pulling the plugs and cranking the water out, only to have it throw a rod while pulling back into my driveway after driving home.

Built the engine up, Comp Cams A6 X4 250H-13 Camshaft, Bored & Align honed, Speed-Pro 3.905 in. Bore Pistons, ported/polished intake, shiny new black paint, and so on. The goal at that time was to have a reliable engine that was street drivable with good mileage. In hindsight, should’ve stroked it, but I’m very happy with the tremendous increase in power it does have over stock.

Fast forward to December 2006, I’ve got a RE 4.5” lift, a semi-built D30/44 combo waiting and ready to go in. The day before I’m set to install it I’m coming home from work I stop at a red light. Next thing I know I’m hit from behind by a dumb woman who was smoking and talking on her cell phone. Insurance totals the Jeep, I buy it back, then purchase an ’03 Silverado.

How my Jeep looked before the accident:

Over the next few months I played the “juggle a bunch of axles at my parents house” game. I literally went through a pair of XJ 30/44, a ’78 F250 HP D44, a ’87 F350 HPD60, then settling on a pair of D60s out of a ’79 F350. All said and done after the swaps I ended up with the ’79 F350 axles for next to nothing. Score. :thumbsup:

When I brought them home (they don't look like this anymore):

After I’d settled on the axles I’m going to be using the parts collecting started and that’s pretty much all I’ve done from then until now. I did clean the axles up and built a GotTrikes Air/Hydro bender with a 1.75” 240 degree die, but more on those later.

So far, I’ve collected a bunch of parts (to many to list), but some of the finer stuff; Precision 5.38s, 35-spline spool, 12’ travel Fox 2.0 Shocks for the front, Crow 5-points, Summit Machine drive flanges, brand new in box 12-bolt H1s, a front D60 T&T truss, BTF rear D60 truss, etc.

I guess I’ll show off a few of the parts :

:

During the parts collecting I cleaned up and stripped both axles down. While I was tackling the rear, I bored out the spindles to accept 35-spline shafts. I did a write-up here on that.

Which now brings me to this past weekend and why I can finally start this build thread. Teardown. I’ve very amazed at how fast one can strip down a XJ. Two days while chipping brush and spreading the mulch during that period in between yields this:

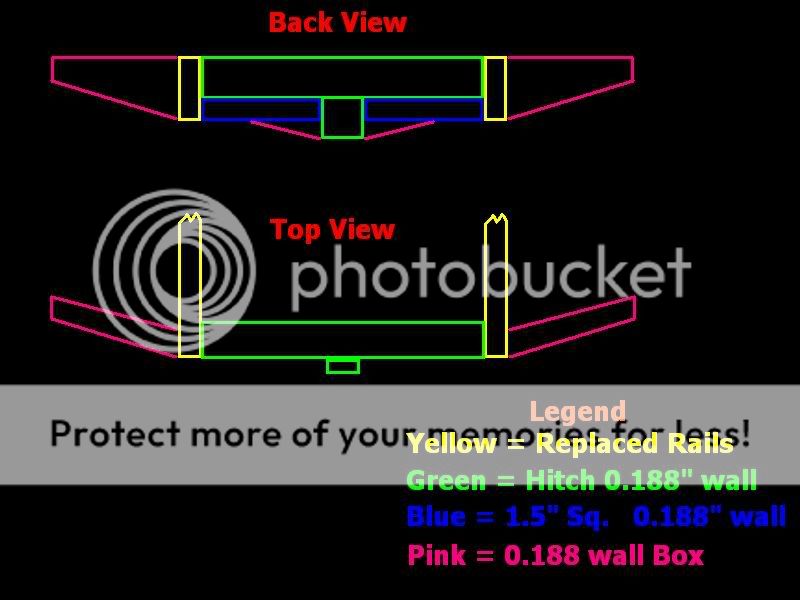

The above pictures don’t do the damage any justice. The sections of floor above the rear portion of the unibody rails are about 1.5-2” higher than they should be, the hitch is toast, the gas tank leaks, sheet metal on the driver’s side is pretty much done, etc.

... so I'll copy what I had started on another forum.

... so I'll copy what I had started on another forum.You 56k people might want to go and grab a 4 course meal and then come back...

FROM 05-19-2008:

Well I guess its finally time for me to start my build thread. I’ve held off for awhile as it wouldn’t have been much to show other than the come and go of the delivery guys. The “Project Downward Spiral” for the sole reason that as soon as I start something, I end up going all out on it and not really gaining much… yet.

Warning: This build will be slow as I’m on a very limited budget, but I’m trying not to cut corners and do it right the first time. Any suggestions, comments, thoughts are welcomed!

The plan as of today (5/19/08):

- Full width D60s, 5.38s Spooled rear, lockright front, alloyed 35-spline everything, flanges.

- H1s with a 38-39.5” tire

- 4-link rear with coilovers

- Drop brackets/short arms up front, RE springs, ACOS, Fox Shocks ( I know the DBs aren’t the best, but I do have them now so they aren’t costing my anything more)

- Chop the top and more the hatch forward

- Cage, suspension seats, Crow 5-points.

- Other stuff I’m forgetting

I’ll start it off with some history for those that don’t know.

Wheeled it for awhile stock, had some fun, and threw on just over 2” lift with ACOS and new HD leafs. Its now December of 2005 and I’ve got an ARB and C4x4 rails. One trip out I had to much fun in and ended up hydro-locking the engine crossing what was thought to be a small brook. Got it running after pulling the plugs and cranking the water out, only to have it throw a rod while pulling back into my driveway after driving home.

Built the engine up, Comp Cams A6 X4 250H-13 Camshaft, Bored & Align honed, Speed-Pro 3.905 in. Bore Pistons, ported/polished intake, shiny new black paint, and so on. The goal at that time was to have a reliable engine that was street drivable with good mileage. In hindsight, should’ve stroked it, but I’m very happy with the tremendous increase in power it does have over stock.

Fast forward to December 2006, I’ve got a RE 4.5” lift, a semi-built D30/44 combo waiting and ready to go in. The day before I’m set to install it I’m coming home from work I stop at a red light. Next thing I know I’m hit from behind by a dumb woman who was smoking and talking on her cell phone. Insurance totals the Jeep, I buy it back, then purchase an ’03 Silverado.

How my Jeep looked before the accident:

Over the next few months I played the “juggle a bunch of axles at my parents house” game. I literally went through a pair of XJ 30/44, a ’78 F250 HP D44, a ’87 F350 HPD60, then settling on a pair of D60s out of a ’79 F350. All said and done after the swaps I ended up with the ’79 F350 axles for next to nothing. Score. :thumbsup:

When I brought them home (they don't look like this anymore):

After I’d settled on the axles I’m going to be using the parts collecting started and that’s pretty much all I’ve done from then until now. I did clean the axles up and built a GotTrikes Air/Hydro bender with a 1.75” 240 degree die, but more on those later.

So far, I’ve collected a bunch of parts (to many to list), but some of the finer stuff; Precision 5.38s, 35-spline spool, 12’ travel Fox 2.0 Shocks for the front, Crow 5-points, Summit Machine drive flanges, brand new in box 12-bolt H1s, a front D60 T&T truss, BTF rear D60 truss, etc.

I guess I’ll show off a few of the parts

During the parts collecting I cleaned up and stripped both axles down. While I was tackling the rear, I bored out the spindles to accept 35-spline shafts. I did a write-up here on that.

Which now brings me to this past weekend and why I can finally start this build thread. Teardown. I’ve very amazed at how fast one can strip down a XJ. Two days while chipping brush and spreading the mulch during that period in between yields this:

The above pictures don’t do the damage any justice. The sections of floor above the rear portion of the unibody rails are about 1.5-2” higher than they should be, the hitch is toast, the gas tank leaks, sheet metal on the driver’s side is pretty much done, etc.