Went down and hung out with Cal today and helped him work on the 4.7 stroker in his Unicorn rig. Russ P has re-worked Cal's Edelbrock head to decrease the experimental high compression ratio (I think it was at 11.4 :1), so we first headed over to Russ's and picked up the head and then headed back to Cal's house to start the task of disassembling his engine. Cal is undertaking a cam swap as well as installing the reworked head and new valvetrain components. The goal for today was to pull all the accessories off the front of the engine, remove the balancer, timing cover and head, as well as pull the camshaft out, and start the engine cleanup, getting everything ready for the install of the new camshaft as well as the reworked head.

Pulling all the accessories off the front of the engine

Getting the head ready to pull - we removed all the rocker arms, push rods and lifters.

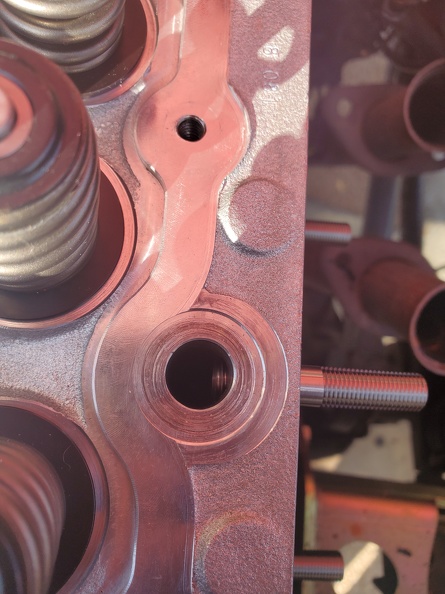

Cal had been having a ton of valve train noise with his engine -and we found that the #3 lifter was bad, had sharp edges and was slightly concave now.

Bad lifter compared to a good one

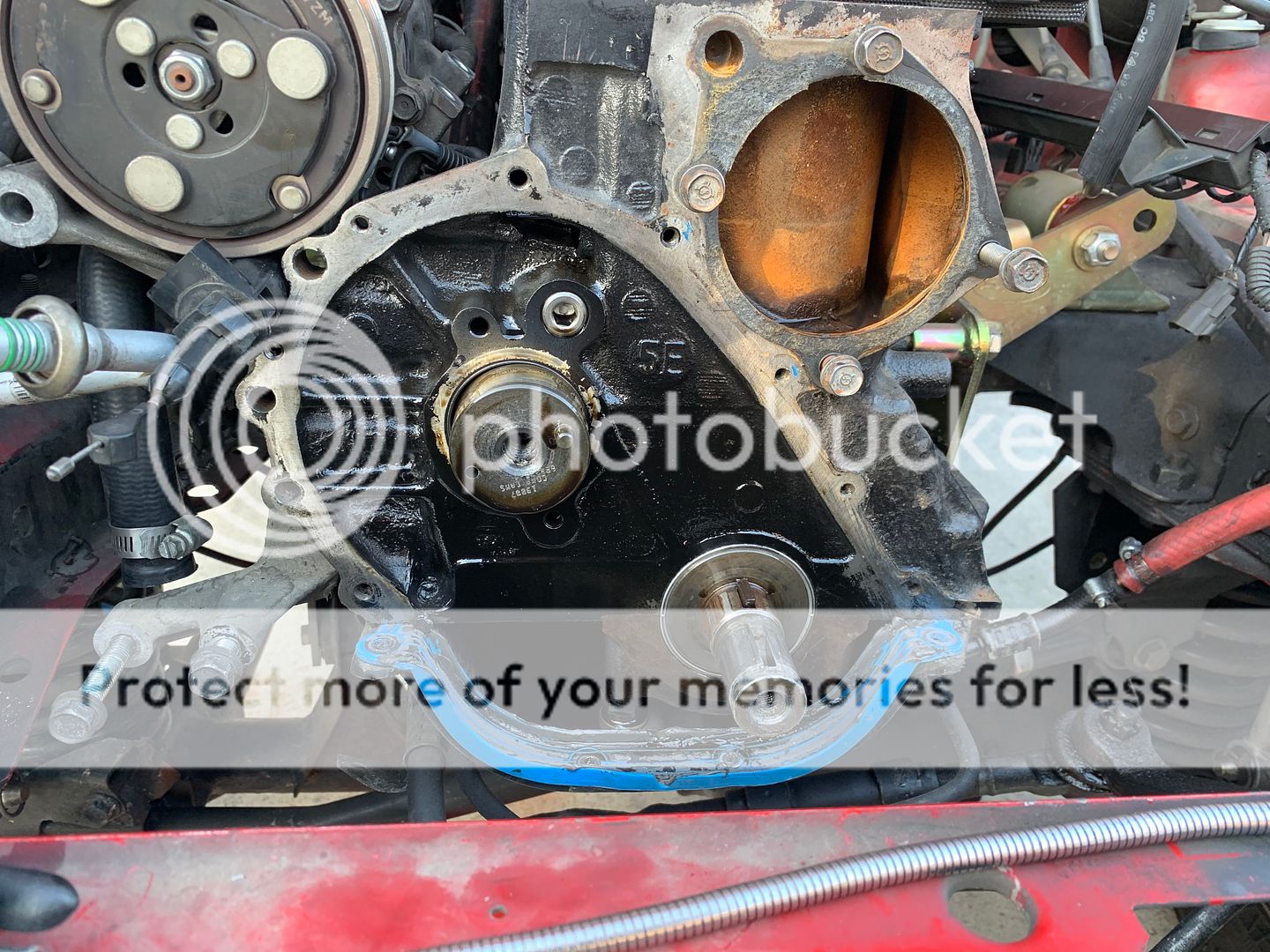

Amazon hadn't delivered the harmonic balancer puller that Cal had ordered, so we ended up heading to lunch, then Harbor Freight down the street, picking up a puller. We then tackled pulling the harmonic balancer, timing cover and the cam.

Cal making sure that the engine was at TDC before pulling the timing chain

Timing gears and chain off and getting ready to pull the cam

It took a little more effort to pull the cam out than we thought. It is hard to get leverage at the back of the cam without removing the oil pan. I ended up just trying to lift the cam up some and slowly pulled it out while rotating it.

After we got the cam out Cal started to work on cleaning the engine up getting it ready for the eventual install. The aftermarket valve cover he has is not baffled well and allows for a large amount of oil to flow into the intake. The pistons had a fair amount of oil on them, that we began to scrape off and clean.

Oil covering the pistons - caused by the poor valve cover.

Cleaning up everything getting it ready for the re-worked aluminum head

It was getting later in the day and would soon be dark, so after getting the piston's pretty clean, we covered up the engine and decided to call it a day! Cal will be back at it tomorrow with a second pass of cleaning up the engine. It is always a good time hanging out with cool

members and helping them wrench on their rigs!

members and helping them wrench on their rigs!

members and helping them wrench on their rigs!