_MURDERED OUT_

NAXJA Forum User

- Location

- Hernando, MS

So my frame ripped behind the steering box, my passenger side exhaust manifold broke in half at the collector, and i decided it was time to re-do the frame to make room for some block hugger headers.

So i ripped the front end off, took everything apart, looked at it for a bit, then the plasma cutter came out. I never knew there was a 2 levels of "frame" in there.

NOW this is how you make room for headers:

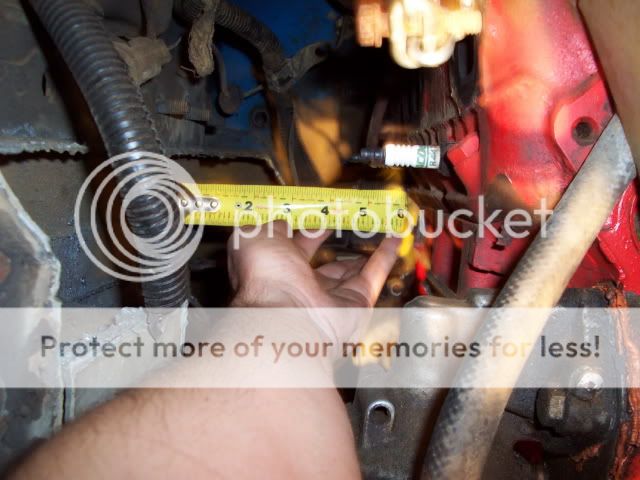

Oh and dont worry, the spring is just hangin out there. There is no weight on the front part of the frame. The pass side spring is out, jackstands under the frame holding the front end up and a jackstand holding the motor up. I was just looking at the space behind the spring for plating clearances...

So i ripped the front end off, took everything apart, looked at it for a bit, then the plasma cutter came out. I never knew there was a 2 levels of "frame" in there.

NOW this is how you make room for headers:

Oh and dont worry, the spring is just hangin out there. There is no weight on the front part of the frame. The pass side spring is out, jackstands under the frame holding the front end up and a jackstand holding the motor up. I was just looking at the space behind the spring for plating clearances...

Last edited: