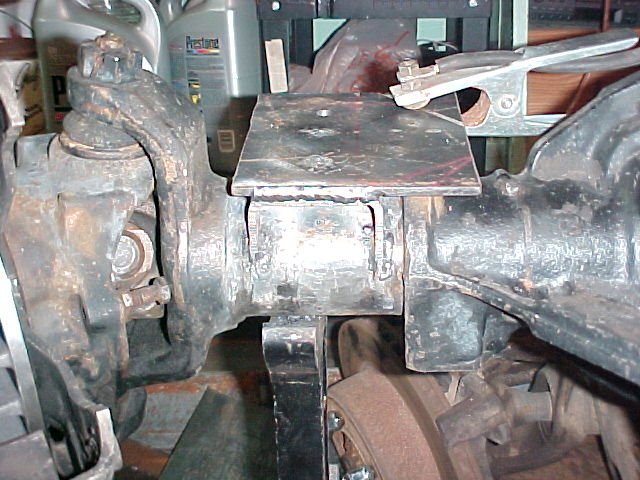

I have been doing my research on the Dana 44 front axle and I have decided on an early Waggy front end which is due to arrive tomorrow. I live fairly close to Currie and after a core, they only want 600 to change the castor and put the brackets on the axle (including all hardware (great price and saves me the hassle)).

I have read (multiple times) the Dana 44 Tech thread by Crash (incredible by the way!) and have been digging through the threads for more information. I have found a lot of answers but I still have a few questions though.

1. I will have about 8-9" of lift on my 94 XJ with an automatic tranny with 35s. The reason for the varience in height is because I will have the ACOS on there so I can adjust my height as necessary. I need to know what angle to have the castor changed to over stock. I did notice BRETTM listed 16 degrees but it seems really high (I did read his reason though). I know Goat has 8" coils (with one cut out) and am curious as to what was done there too. Any thoughts? I would like to drop the axle off this week and provide them with an angle.

2. I got two flat knuckles off a 70s Chevy Blazer and am hoping to go high steer on this project. Currie (when they weld all of my brackets on my waggy axle) says the brackets will be identical to the Dana 30 (in regards to positioning). My concern is that with the high steer, I will hit the coils when turning to both extremes. Is there any way around that? I asked them if they (Currie) could re-position the coil pads back one inch but they couldn't. Also, I need to know who I can send out my knuckles to to be machined (and have the studs installed) AND purchase the proper high-steer arms (and possible a heavy duty tie rod and drag link).

3. I have the Chevy brakes all ready to go but...will the stock XJ braking hardware work on these brakes or do I need to change the proportioning valve or anything else to get it to work?

I know I am asking a lot here on one thread but I appreciate all the help I can get.

-Avery aka CRACKER

I have read (multiple times) the Dana 44 Tech thread by Crash (incredible by the way!) and have been digging through the threads for more information. I have found a lot of answers but I still have a few questions though.

1. I will have about 8-9" of lift on my 94 XJ with an automatic tranny with 35s. The reason for the varience in height is because I will have the ACOS on there so I can adjust my height as necessary. I need to know what angle to have the castor changed to over stock. I did notice BRETTM listed 16 degrees but it seems really high (I did read his reason though). I know Goat has 8" coils (with one cut out) and am curious as to what was done there too. Any thoughts? I would like to drop the axle off this week and provide them with an angle.

2. I got two flat knuckles off a 70s Chevy Blazer and am hoping to go high steer on this project. Currie (when they weld all of my brackets on my waggy axle) says the brackets will be identical to the Dana 30 (in regards to positioning). My concern is that with the high steer, I will hit the coils when turning to both extremes. Is there any way around that? I asked them if they (Currie) could re-position the coil pads back one inch but they couldn't. Also, I need to know who I can send out my knuckles to to be machined (and have the studs installed) AND purchase the proper high-steer arms (and possible a heavy duty tie rod and drag link).

3. I have the Chevy brakes all ready to go but...will the stock XJ braking hardware work on these brakes or do I need to change the proportioning valve or anything else to get it to work?

I know I am asking a lot here on one thread but I appreciate all the help I can get.

-Avery aka CRACKER

Last edited: