-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TOTM: Front control arms

- Thread starter crazyjim

- Start date

tbburg

NAXJA Forum User

- Location

- Scottsdale AZ

For the short arm suspension: We run the stock control arms on the race truck - no bracing or reinforcement. (quit laughing, it's a BITD class requirement :rof: ) Interestingly, while we've taken hits hard enough to bend the track bar, and to warp the spring pad/bump stop area, bent the front axle truss, and generally tear up the truck we've never managed to damage a control arm.(What's really funny is we have a full set of spares we carry on the truck. :dunno: )

A lot of people make the assumption that the stock arms are weak because they will twist as the suspension moves. They miss the fact that the arms are supposed to twist. If you braced the arm enough where it wouldn't twist, all the play would be taken up in the bushings, and they would wear out and tear pretty quickly. Because of the geometry of the stock link setup, there has to be both fore and aft, and side to side play in the system. That's why the huge rubber bushings and twisty links.

Generally when you see someone with a broken passenger side upper control arm mount, you see the rig has solid one-piece link arms with hard poly bushings or heim joints. When you take all the play out of the system, the weakest link becomes the passenger side upper control arm mount. Which twists and flexes until it breaks off.

As long as you're not bashing rocks into the arms, the stock arms probably won't be the first thing to break.

A lot of people make the assumption that the stock arms are weak because they will twist as the suspension moves. They miss the fact that the arms are supposed to twist. If you braced the arm enough where it wouldn't twist, all the play would be taken up in the bushings, and they would wear out and tear pretty quickly. Because of the geometry of the stock link setup, there has to be both fore and aft, and side to side play in the system. That's why the huge rubber bushings and twisty links.

Generally when you see someone with a broken passenger side upper control arm mount, you see the rig has solid one-piece link arms with hard poly bushings or heim joints. When you take all the play out of the system, the weakest link becomes the passenger side upper control arm mount. Which twists and flexes until it breaks off.

As long as you're not bashing rocks into the arms, the stock arms probably won't be the first thing to break.

yossarian19

NAXJA Forum User

- Location

- Grass Valley, CA

For the short arm suspension: We run the stock control arms on the race truck - no bracing or reinforcement. (quit laughing, it's a BITD class requirement :rof: ) Interestingly, while we've taken hits hard enough to bend the track bar, and to warp the spring pad/bump stop area, bent the front axle truss, and generally tear up the truck we've never managed to damage a control arm.(What's really funny is we have a full set of spares we carry on the truck. :dunno: )

A lot of people make the assumption that the stock arms are weak because they will twist as the suspension moves. They miss the fact that the arms are supposed to twist. If you braced the arm enough where it wouldn't twist, all the play would be taken up in the bushings, and they would wear out and tear pretty quickly. Because of the geometry of the stock link setup, there has to be both fore and aft, and side to side play in the system. That's why the huge rubber bushings and twisty links.

Generally when you see someone with a broken passenger side upper control arm mount, you see the rig has solid one-piece link arms with hard poly bushings or heim joints. When you take all the play out of the system, the weakest link becomes the passenger side upper control arm mount. Which twists and flexes until it breaks off.

As long as you're not bashing rocks into the arms, the stock arms probably won't be the first thing to break.

Great info!

whooprunner

NAXJA Forum User

- Location

- Orange County, CA

Currently installing Full Traction's Long Arm Kit. I really like the geometry, but I hate the way the upper control arms mount. It uses a 9 inch long bolt that runs through the unibody rail to catch the control arm on the other side. Trying to line up all the brackets and unibody rail to allow that 9 inch bolt to slide in smoothly is a pain in the butt. The other problems is that Full traction is the only one you can buy that bolt from.

If I was going to do it again, I think I would go with this kit:

http://www.polyperformance.com/shop...avel-Front-Rear-Kit-4-Link-Front-p-25694.html

If I was going to do it again, I think I would go with this kit:

http://www.polyperformance.com/shop...avel-Front-Rear-Kit-4-Link-Front-p-25694.html

- Location

- San Diego

im running rubicon express superflex arms along with their drop brackets. i have no complaints about them as they flex very well. but i have yet to use them at any decent speed in the dirt. personally i would rather be running a 3-link with a trackbar much like XJRUNNER is using

WESJxj

NAXJA Forum User

- Location

- huntington beach ca

I had the Rubicon super flex arms originally and ran them for a few years with 2 in fox resivors. They worked great! Then i came across a guy that got me the whole front kit from full traction( The long arm kit) for 300.00 bucks. I could'nt pass that up. Now they are installed, they cycle good, have 1.25 hiems at the axle side and flex joints at the cross member. Everything looks strong. I cant wait to test them out especaily since ive upgraded to foa 2.5 shocks frnt and rear(10 in stroke frnt, 14 stroke rear) it should be nice!!!!!

h-townxj

NAXJA Forum User

- Location

- Hanford, Ca

On my xj we Ran the rcx lift one time and the front did pretty well with their fixed lowers stock uppers and drop brackets better than my other 2 jeeps it's all about geometry really and strong arms had no problem wtb the stock uppers failng and crazyjim knows about using his stock uppers also

HollisM16

NAXJA Forum User

- Location

- Colorado Springs, CO

I'd like to hear the opinions of folks about a y-link setup... preferably people who have run it in the desert. =)

I'm running TnT's long-arms with coilovers up front and think it's a great system, but people keep saying I should take off the passenger upper arm of the Y-link to prevent binding. Thoughts?

I'm running TnT's long-arms with coilovers up front and think it's a great system, but people keep saying I should take off the passenger upper arm of the Y-link to prevent binding. Thoughts?

ratboy93

NAXJA Forum User

- Location

- alta loma, ca

Currently installing Full Traction's Long Arm Kit. I really like the geometry, but I hate the way the upper control arms mount. It uses a 9 inch long bolt that runs through the unibody rail to catch the control arm on the other side. Trying to line up all the brackets and unibody rail to allow that 9 inch bolt to slide in smoothly is a pain in the butt. The other problems is that Full traction is the only one you can buy that bolt from.

If I was going to do it again, I think I would go with this kit:

http://www.polyperformance.com/shop...avel-Front-Rear-Kit-4-Link-Front-p-25694.html

that bolt its a mother f. i hate that bolt.. be carefull before torqueing that metal lock nut on. make sure everything is perfect because that nut aint coming off... i turned up my IR impact and it still wouldnt come off. so my passengerside control arm is on upsode down still.. but my heep just sits in the garage and i havent switched it yet so im not too worried about it...

grandrunner

NAXJA Forum User

- Location

- La Quinta, SoCal

not an xj, but im running claytons front long arms with deaver coils and 11inch 2.0's on the zj. hit whoops and jumps and soaks up everything so far. way smoother than my short arm set up. unbeleivable difference. does good for crawling too.

grandrunner

NAXJA Forum User

- Location

- La Quinta, SoCal

I'd like to hear the opinions of folks about a y-link setup... preferably people who have run it in the desert. =)

I'm running TnT's long-arms with coilovers up front and think it's a great system, but people keep saying I should take off the passenger upper arm of the Y-link to prevent binding. Thoughts?

from what ive heard and experienced. only rock crawlers need to worry about binding up the arms when articulating. the added 4th arm is also adding strength to the front end. someone correct me if im wrong...

because before my clayton 4link i ran the iron rock offroad 3link setup. but dont get me wrong i loved the iro kit. did most of the same driving as with my clayton kit. only reason i changed was because the iron rock wasnt adjustable and didnt work with my tnt axle truss.

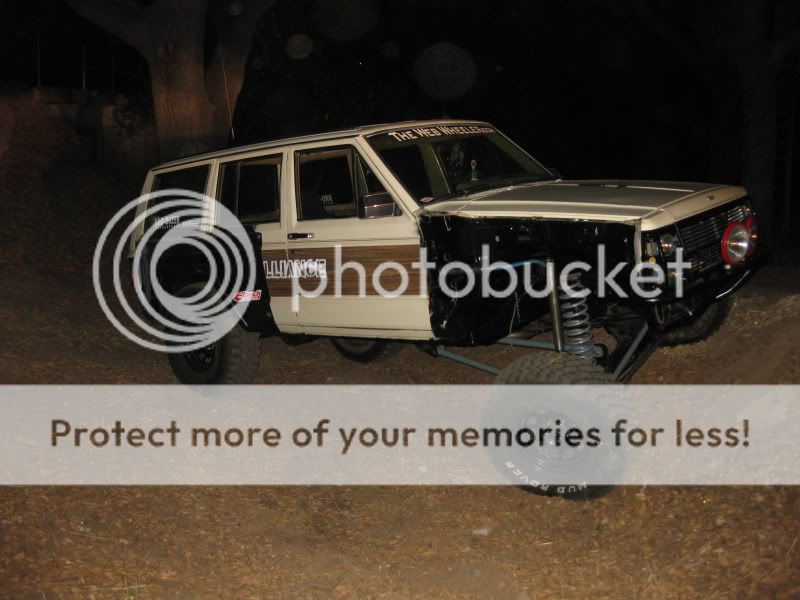

pics of the 3link.

grandrunner

NAXJA Forum User

- Location

- La Quinta, SoCal

and both clayton and iro kits are available for the xj

whooprunner

NAXJA Forum User

- Location

- Orange County, CA

that bolt its a mother f. i hate that bolt.. be carefull before torqueing that metal lock nut on. make sure everything is perfect because that nut aint coming off... i turned up my IR impact and it still wouldnt come off. so my passengerside control arm is on upsode down still.. but my heep just sits in the garage and i havent switched it yet so im not too worried about it...

LOL I made that mistake already and had a helluva time trying to get that nut off. Ended up running a tap through it so it'll act like a regular lock nut. Dealing with that bolt/nut issue almost made me wanted to make me go back to Rubicon Express's long arm.

Mike1331

NAXJA Forum User

- Location

- Folsom, CA

RE uppers's lowers w/ drop brackets and my cage tied into the brackets, feels great at speed.

I was talking to a jeepspeed guy at a vorra race here at prairie city who was running drop brackets and he said the drop bracket short arm set up was faster than a long arm set up. I immediatly stopped the search for long arms.

Can anybody validate this?

It makes sense though because short arms are lighter therefor creating less unsprung weight on the axle end equaling less work for the shocks and less stress on bracketry n such.

I was talking to a jeepspeed guy at a vorra race here at prairie city who was running drop brackets and he said the drop bracket short arm set up was faster than a long arm set up. I immediatly stopped the search for long arms.

Can anybody validate this?

It makes sense though because short arms are lighter therefor creating less unsprung weight on the axle end equaling less work for the shocks and less stress on bracketry n such.

whooprunner

NAXJA Forum User

- Location

- Orange County, CA

RE uppers's lowers w/ drop brackets and my cage tied into the brackets, feels great at speed.

I was talking to a jeepspeed guy at a vorra race here at prairie city who was running drop brackets and he said the drop bracket short arm set up was faster than a long arm set up. I immediatly stopped the search for long arms.

Can anybody validate this?

It makes sense though because short arms are lighter therefor creating less unsprung weight on the axle end equaling less work for the shocks and less stress on bracketry n such.

While I agree that short arms are lighter, I would not say there is less stress on bracketry including drop brackets.

The comparison being made is like saying an xj with a dana 44 rear end is going to faster than an xj with a ford 9 inch because the dana is lighter. There are so many other variables at hand, that in the end you can't blatantly say which is really going to be faster.

The thing that long arms really buy you are better geometry/easier cycling of the suspension during setup.

Either arm style if setup properly will be fast. The reason there are myths about short arms being faster in JeepSpeed is because Ray Griffith was a great/fast driver and just happened to have short arms.

-Randy

- Location

- Yucaipa, CA

Most of the really fast guys on short arms are driving older jeepspeed rigs. When a lot of those cars were built, there really weren't any approved companies that made a long arm kit...so they refined what they had available, and they did it well. I don't think the long arm vs short arm debate is a valid one in the 1700 class, as they will both cycle 10 inches easily. The debate would be in the set up as to "which one is faster."

Back when I was doing the rock crawling thing with mine, when I went to the long arms, I really didn't notice any vast improvement in performance. I never had drop brackets with my short arms, but I modified the control arm mounts on the axle and frame side uppers to do pretty much the same thing...only without using the drop brackets.

When I added the RE radius arms, on my own crossmember, I had even less steep angles which worked great for overall driveability.

The drop brackets' only purpose is to get the control arm angles and geometry closer to stock with less angle on the arms, which will in turn, ride smoother. So I really don't think one is better than the other with such limited wheel travel.

Back when I was doing the rock crawling thing with mine, when I went to the long arms, I really didn't notice any vast improvement in performance. I never had drop brackets with my short arms, but I modified the control arm mounts on the axle and frame side uppers to do pretty much the same thing...only without using the drop brackets.

When I added the RE radius arms, on my own crossmember, I had even less steep angles which worked great for overall driveability.

The drop brackets' only purpose is to get the control arm angles and geometry closer to stock with less angle on the arms, which will in turn, ride smoother. So I really don't think one is better than the other with such limited wheel travel.

FatCity Ryan

NAXJA Forum User

- Location

- Wildomar, Ca

I was talking to a jeepspeed who was running drop brackets and he said the drop bracket short arm set up was faster than a long arm set up.

Can anybody validate this?

I can validate that this is wrong or right easily! Who were you talking too?

The reason there are myths about short arms being faster in JeepSpeed is because Ray Griffith was a great/fast driver and just happened to have short arms.

-Randy

Griffith has short arms with no drop brackets. Ray Currie says this is the only way to race an XJ. Worked for Griffith.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 24

- Views

- 425

- Replies

- 7

- Views

- 2K

- Replies

- 28

- Views

- 1K