alex22 said:

When you say that the #7120 "is bordreline to support the larger valves" do you mean that the head is thin around the seat and there might not be enough iron to keep the valve from crushing into the water jacket?

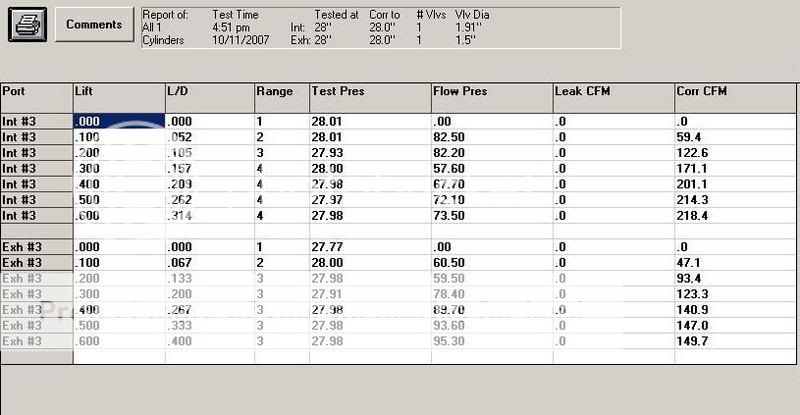

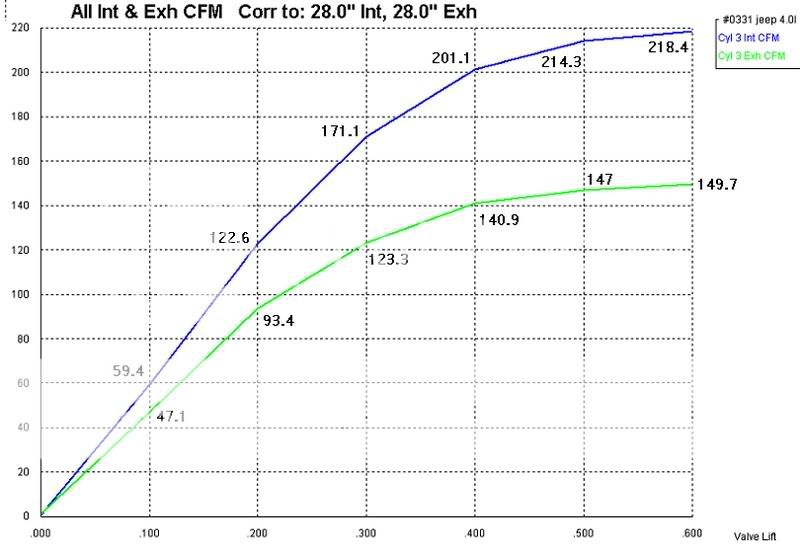

The porting and flow bench work is not really a problem for me since I am the one who would be doing the work. The shop has a Superflow SF-600 with the flow com computer and Performance Trends software hooked up to it.

I am mainly concerned about how low the flow on the exhaust is. I would like to put the 1.6 Ex valve. The stock flow numbers on Dino's site say that the exhaust only flows 68% of the intake.

The XJ will be a daily driver and might see some offroad/haulin down dirt road paths once in a while. I want to build it more for low end torque than high RPM HP, within safe power limits of the 5spd and DANA 35. I don't actually need the new engine but since I can do all the work myself and get the parts through work I really don't see why not.

I saw on Dino's site that the 00-06 intake manifold has smaller runers and is better for torque. Will that manifold fit on the 7120 head with a port match or are the bolt holes in diferent spots?

~Alex

Later manifolds should all swap (1991-up,) but a quick way to tell is to check the gaskets. If you can lay them all one on the other and see through the screw holes, you're good (I don't think the ports moved past 1991, but the exhaust ports were reduced slightly in 1999/2000 to improve catalyst light-off.)

If you have access to a number of heads, I'd like to see raw flow data for lift in .100" increments, including .100" (I've got some flow data, but it's different heads, different operators, and different benches. So, some error has to be assumed...) I'm also trying to collect heads for analysis - if you get any warped/cracked heads in for the AMC six, I'd like to hear about it. If your PT software also supports cam measurement and you get access to OEM AMC six cams, I'd appreciate data on those as well (since definitive data on OEM and MPP cams is difficult to find, and I'd like to flesh out both sections of my book...)

By "borderline," I'm more meaning that the head just isn't designed to flow that much air. I'd really want to put seats in anyhow (I don't think you'll hit the water jacket, but I'd rather "hit and fill" than guess...) but it would take an awful lot of massaging to make the big valve work useful - especially at low RPM (which would benefit more from an aggressive cam than valve opening anyhow.)

So, you're not trying to build a stump puller - that should help (although you should make sure that your Dana 35 isn't the "C-clip" version...) And, since you've got a 1996, you've got the AX-15 5-speed, which will support some mild engine improvements. At least it's not the damned Peugeot... If you go too far, you're going to want a better box - the NV3550 comes to mind - but you shouldn't have too much trouble with the AX-15 (provided you keep it on a steady diet of GL-3.)

I think you'll find that most production heads in the last 15 years or so don't have the exhaust flow that they really should - mainly, to reduce catalyst light-off times (keeping the ports small helps the hot gasses get there faster, which gets the catalyst up to its operating temperature faster. Not entirely sure I like that solution, tho - it increases pumping losses and parasitic drag, reducing specific power output and specific fuel consumption...)

The only "real" manifold change that I can think of happened 1990/1991, when the ChryCo OBD-II system was added, the #7120 head was introduced, and the intake ports were raised about 5/8" to improve intake airflow (by reducing the angle that the flow had to go through to get into the chamber.)

If you want to discuss this at length, we may have to go backchannel - but this has a lot to do with why I've written the

Power Manual (information on my website and at groups.yahoo.com/group/JeepPower - it's a "support group" for the book.) There's a link in my sig.