Talyn

NAXJA Forum User

- Location

- Radford, Communistwealth of Virginia

I've had this posted on JeepStrokers.com for a while so I figured I would post this here.

I'm working on a new 4.6L stroker to replace that Titan stroker I have.

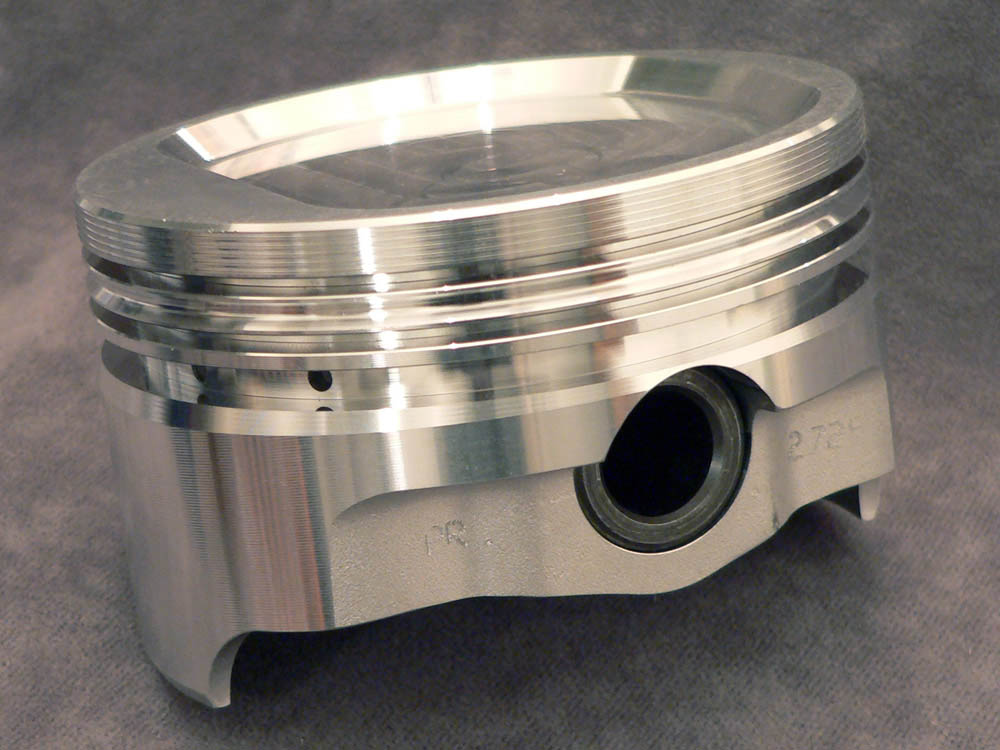

Basically, I am using .030" over KB944 forged pistons 4.0L rods, a 2000 block, comp cam 68-231-4. Harland Sharp roller rockers, 25lb injectors, 63mm throttle body, 2000 Turbo X coated Doug Thorley header, and a ported and polished head. I'm shooting for 9.58 static compression ration, 8.19 dynamic compression ratio and a .044" quench. I'm going to try to pull off running regular gas.

Main bearings - Clevite 77 TM - Ms1947P

Cam bearings - Clevite 77 - SH1980S

Rod bearings - Clevite - CB960P x6

Oil pump - Melling - mel-M81A

Freeze plugs - Pioneer - PE-256-BR

Rod bolts - ARP - 112-6001

Pistons - KB - KB 944

Crank spacer - Hesco

Timing set - JP performance Billet - JP5629

Crank - 4 counter weight 4.2L

Rods - 4.0L rods, polished and cryo tempered

Cam - Comp Cam - 68-231-4 - Comp cam

Lifters - comp-cam

Mopar Performance .041" MLS head gasket.

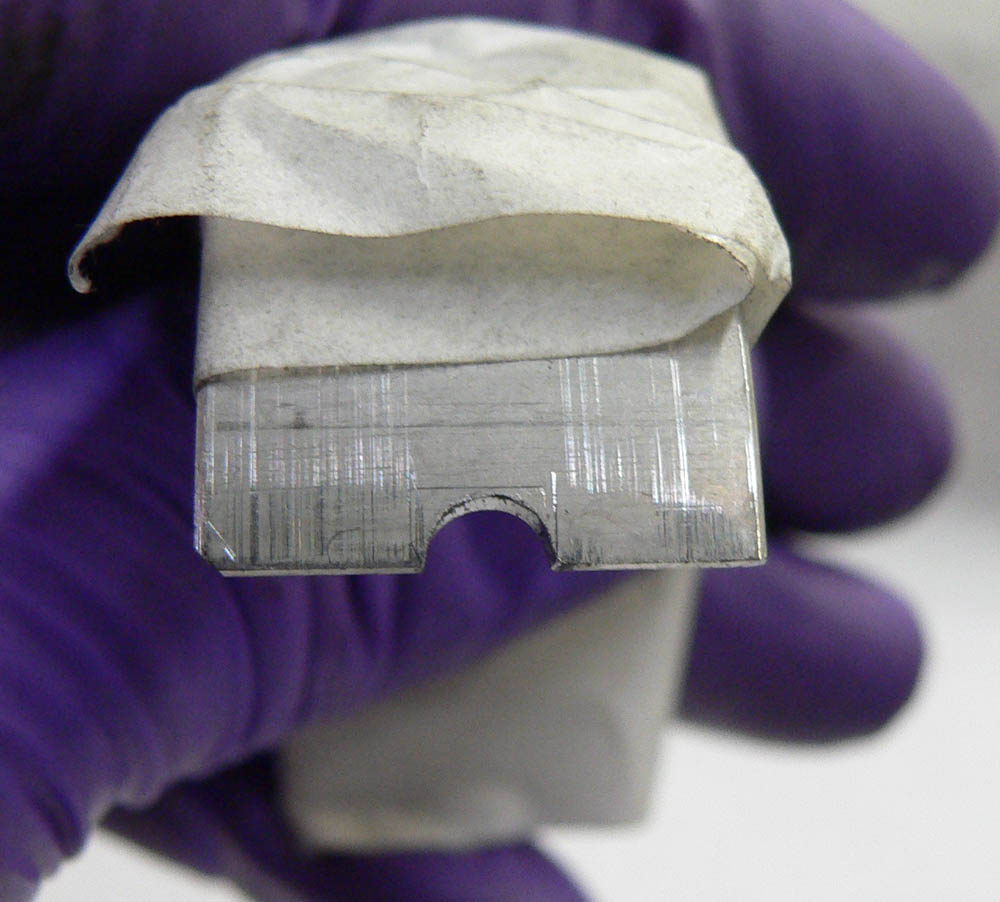

I had to modify the rod bearing because they orginally didn't have any occomidation for the oil squirt hole in the rods.

Polished rods:

]img]http://jeep.blackonyx.net/forum/kb94446l/P1200314.JPG[/img]

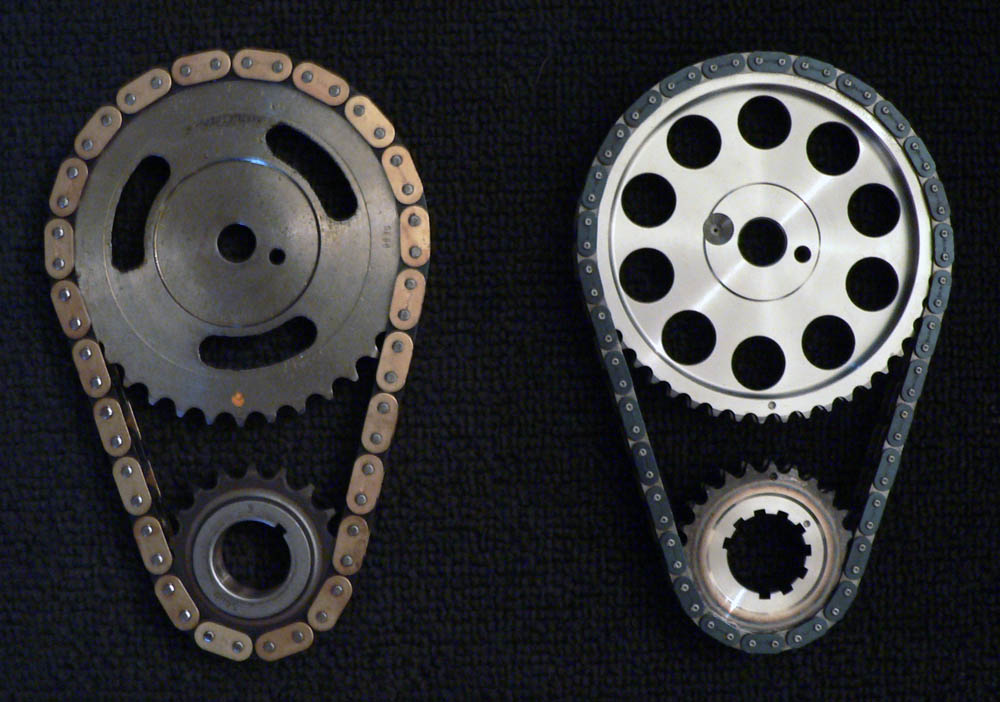

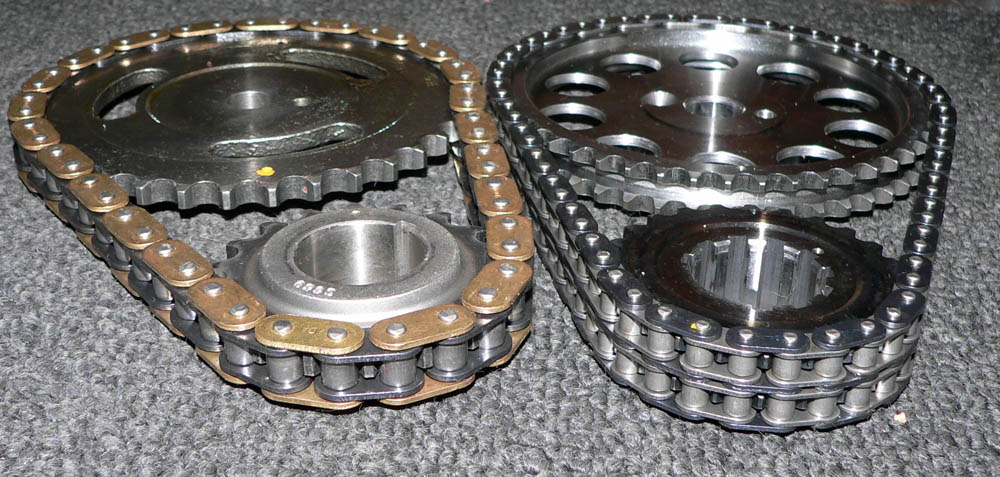

The next pics are of the JP Performance timing set (on the right) compared to some single timing chain set. The JP set is a thing of beauty compared to the other one. One thing that is interesting is the number of teeth compared to the old one. The JP timing set has may more.. no, I am not counting them. Has anyone remived the tensioning block and removed it's brackets from the cover? Some where I heard that this is necessary on a double rolled set, but I don't remember where I picked that up.

Pistons:

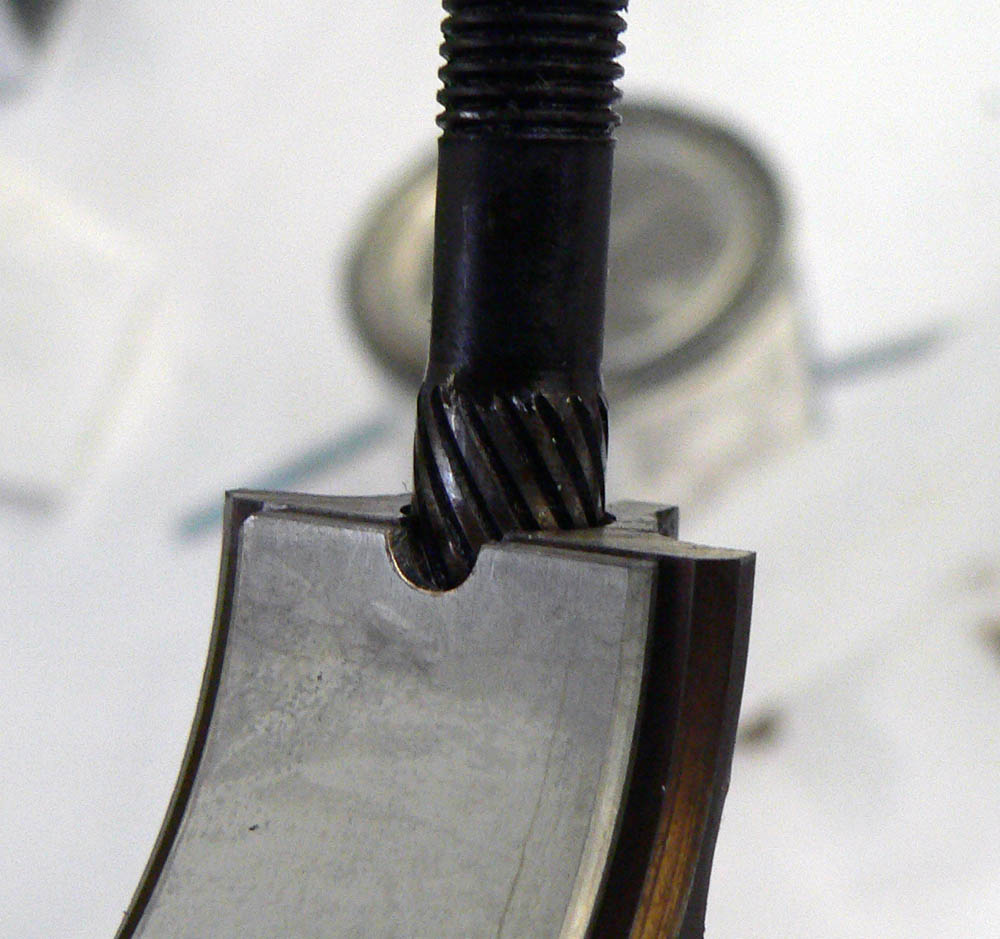

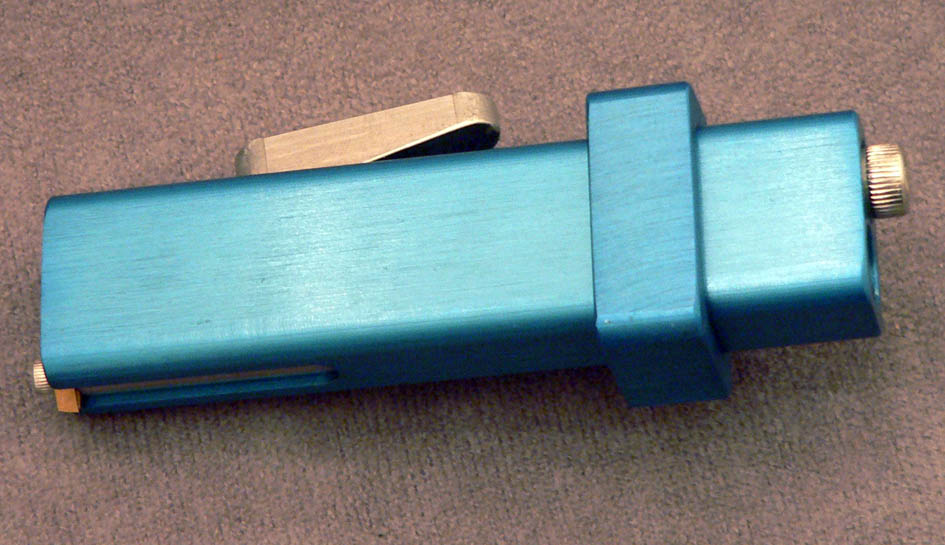

I'm going to groove the lifter bores to push more oil to the cam lobes as well. Lifter bore grooving tool:

I'm working on a new 4.6L stroker to replace that Titan stroker I have.

Basically, I am using .030" over KB944 forged pistons 4.0L rods, a 2000 block, comp cam 68-231-4. Harland Sharp roller rockers, 25lb injectors, 63mm throttle body, 2000 Turbo X coated Doug Thorley header, and a ported and polished head. I'm shooting for 9.58 static compression ration, 8.19 dynamic compression ratio and a .044" quench. I'm going to try to pull off running regular gas.

Main bearings - Clevite 77 TM - Ms1947P

Cam bearings - Clevite 77 - SH1980S

Rod bearings - Clevite - CB960P x6

Oil pump - Melling - mel-M81A

Freeze plugs - Pioneer - PE-256-BR

Rod bolts - ARP - 112-6001

Pistons - KB - KB 944

Crank spacer - Hesco

Timing set - JP performance Billet - JP5629

Crank - 4 counter weight 4.2L

Rods - 4.0L rods, polished and cryo tempered

Cam - Comp Cam - 68-231-4 - Comp cam

Lifters - comp-cam

Mopar Performance .041" MLS head gasket.

I had to modify the rod bearing because they orginally didn't have any occomidation for the oil squirt hole in the rods.

Polished rods:

]img]http://jeep.blackonyx.net/forum/kb94446l/P1200314.JPG[/img]

The next pics are of the JP Performance timing set (on the right) compared to some single timing chain set. The JP set is a thing of beauty compared to the other one. One thing that is interesting is the number of teeth compared to the old one. The JP timing set has may more.. no, I am not counting them. Has anyone remived the tensioning block and removed it's brackets from the cover? Some where I heard that this is necessary on a double rolled set, but I don't remember where I picked that up.

Pistons:

I'm going to groove the lifter bores to push more oil to the cam lobes as well. Lifter bore grooving tool:

needs to see this stuff too though. Good job

needs to see this stuff too though. Good job